Application Trend of Motion Plastics in Seat Systems

Lynna Liu (刘银) | August 7, 2020

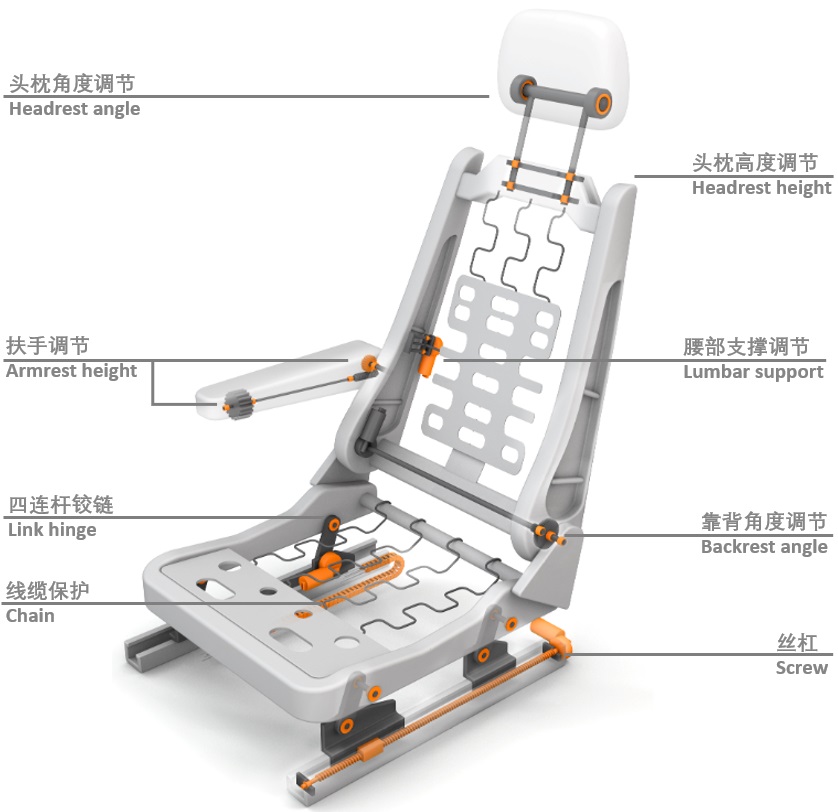

On June 27, 2020, Shanghai officially announced the launch of Didi’s self-driving service online, which signify that driverless technology and applications have basically matured. Without a driver, or the driver adjusts to automatic driving mode, the internal space of a car can be transformed into entertainment room,or games, rest , meeting room. Passengers can adjust backrest or rotate seat into a face-to-face meeting mode. Function of the seat will become more and more plentiful. In addition to the bushes at the hinges of in seat frame that we have known in the past, the advantages of motion plastics will extend to the core parts of actuators, slide rails, slewing ring bearings, screw nuts, chains, and so on.

Hinge bushing

The traditional metal bushing has always layered structure. There will be problems with the self-lubricating coating when being kicked off during installation,for example , noise increase, firmness disappears, and the seat frame will loose or even shaken. While plastic bushing is always injection molded from a uniform and integrated material. Self-lubricating particles are embedded between the material molecules, which can maintain long-term and reliable lubrication between the moving pairs.

In addition to structural differences, plastic bushings have many other advantages compared to traditional metal ones. The weight of one DU bearing is equivalent to 7 iglidur bearings,that means weight of plastic is much lighter. Thanks to injection molding process, structural design of plastic bearing can be more flexible and diverse than metal rolled bushings. Therefore, we will let them born with flanges and even add other functions. Compared with metal bushings, injection-molded plastic sets can greatly simplify the installation steps of bushings during seat assembly and save investment in tooling equipment.

Last but not least,can plastic bushings go through the electrophoresis drying process? It’s a really big point that engineers are generally concerned about. The seat frame generally uses the electrophoresis process to prevent the metal components from rusting. The iglidur bushing not only has been proven through a large number of cases, but it can also compensate for the gap and reduce the degree of dependence on the accuracy of housing bore. The following video illustrates the change of a clip-on structure bushing during electrophoresis drying process: the accuracy of sheet metal punching is often at the level of H10~H11, and the ambient temperature is kept at 160℃~200℃ for 20~30min. Such a condition will let the plastic material of the interference installation become soft, calibrate the tolerance, and fit on the punching surface after cooling down. This process can make up for the lack of punching accuracy and ensure the damping feeling when the shaft rotates. At the same time, the plastic bushing also forms a self-protection from cutting by burrs and notches.

Slewing ring bearing for seating

As the majority of car owners have higher and higher requirements for the comfort and intelligence of car seats, the demand for multi-directional adjustment is increasing. In the luxury seat industry of refined vehicles, it is not uncommon for the entire chair to rotate 360°. PRT slewing ring bearings are installed on the chassis of the seat. The sliding elements are iglidur J materials with low friction coefficient, which benifit driving torque and make the operation more quiet. PRT slewing bearings need much smaller space and have wide range of available sizes now.https://www.igus.com.cn/prt/slewing-ring

Linear rail and self-lubricating sliding elements

When headrests, armrests and leg rests have linear sliding functions, they usually need to have self-locking or damping effects. Drylin N pre-tightening and self-locking guide rails provide the perfect solution. The sliding element is made of self-lubricating plastic material. So there is no need to add lubricant, which can keep the interior space of the car clean and tidy. Compared with linear ball bearings, there is no noise and high cost performance. To get more knowledge of existing standard products, please click:https://www.igus.com.cn/drylin/linear-guide?sort=3&fc=301211&inch=false

headrest

armrest

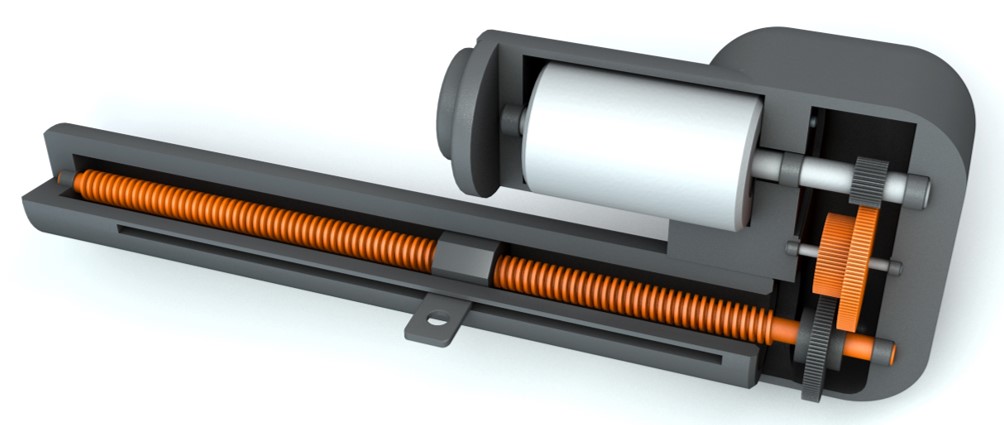

Electronic actuator

It has gone through a short time for seat adjustment tech to upgrade from manual to electric. In a seat system, every adjustment is driven by electronic actuators. With the coverage of automotive intelligent products become more and more common., these driven components will also be used. iglidur plastics, especially materials that can withstand higher temperatures, do not require lubricants, avoiding the problem of grease failure in core parts. At the same time, it has higer wear resistance and cost effcient than copper bearings or powder metallurgy bearings.

In electronic actuator components, transmission gears, screw pin and matching nuts usually also arouse great interest. igus can provide high-efficiency patent dryspin screw pin. Customers can use online screw configurator and online gear configurator to self-design and download drawing, and even use online 3D printing services to quickly get sample quotations and place orders.

actuator

seat actuator

screw and nut ,gear application

Cable protection

The chain system is used to provide guidance for cables and have anti-torsion protection in car seat adjustment or any other power supply systems .

Future seat functions and interior development

Inside the multifunctional car, the steering wheel can be hidden, the seat can be moved back and forth and rotated, the drivers and passengers can meet face-to-face, and the central control main dashboard is split and merged into two complete large screens. These actions are not too difficult to realized in technical aspect. By choosing self-lubricating plastic materials as moving elements in sliding and rotating positions, end users will truly experience a quiet and clean car environment and excellent product quality.

Products and services

Self-lubricating plastics are found in various motion components. If you are interested in any of these applications , please feel free to contact me. Free test samples of standard parts can be responded within 24 hours, and we also provide customized development services .

bushing sample box

drylin sample box

drytech on board

chain&cable on board

刘银/Lynna Liu

电话:021-80366201

邮箱:lyliu@igus.net