Severe contamination by salt or sugar … what must be observed?

Ahren Xia | December 23, 2020

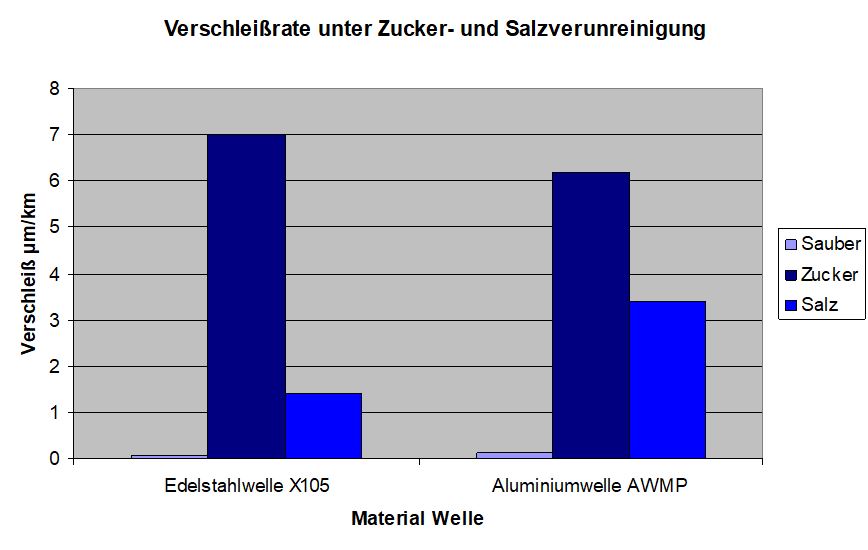

Wherever food or beverages are processed, filled or packed, contamination can occur. If it is salt or sugar, it is important to take a close look at the abrasive (rubbing/grinding) wear. In this way it can be determined what influence this has on the plain bearing or linear guide.

In order to examine such contamination, we simulated sugar and salt contamination respectively in our test laboratory on a linear friction coefficient test rig. A viscous sugar solution was applied on the shaft. The experiment was not started until the sugar had dried. This process was repeated daily.

The saline solution was applied on the shaft; then the experiment was started immediately. This process was repeated twice a day. (Drying of the salt solution before restarting did not result in a sufficient contamination effect)

Conclusion of the test: as can be seen on the wear chart, drylin R linear guides function on both tested X105 stainless steel and aluminium shafts with dried sugar solution and salt contamination. However, bearing wear and coefficient of friction are higher than when operating under clean ambient conditions. Regular cleaning of the application is therefore recommended in order to achieve a longer service life of the components used.

If you have more questions, please feel free to contact us!

Ahren Xia

Industry Manager Packaging

Email:axia@igus.net

Phone:021-8036 6455

Fax:021-8036 6447