Lead screw technology in the DIY beer lift

Kevin Huang | September 25, 2020

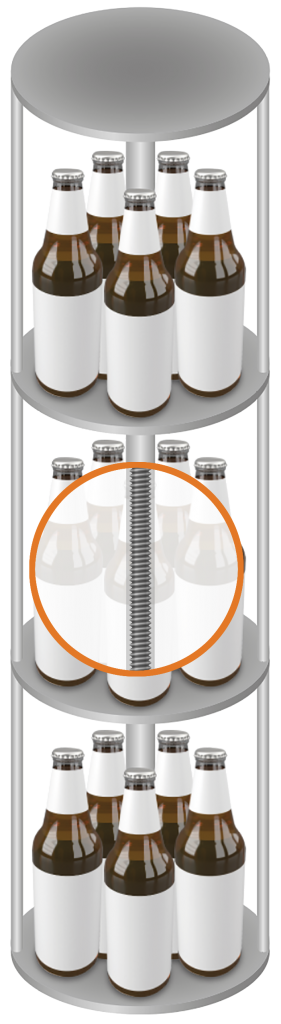

Beer lift light built with maintenance-free lead screw technology.

High temperatures in summer, the need for a cool drink but no desire to constantly run to the fridge? The self-built beer lift provides a solution. Up to 21 beverage bottles can be cooled in the stylish beer lift. Completely without electricity and as a highlight of every party.

On the Internet you can find numerous DIY instructions for constructing a beer lift. Here is our top recommendation (in german): https://www.bierlift.de/bierlift-projektbeschreibung/

A decisive point for the smooth application of the beer lift is the use of the correct high-helix thread system. The length of the lead screw is approx. 1 metre. In order to be able to guarantee the service life as long as possible, there are two important points to consider:

- Sustaining high torques: The high-helix lead screw drives the beer lift by means of a suitable gear motor. The motor achieves about 100 revolutions per minute and has a sufficiently high torque. The high helix lead screw must withstand the loads without any problems.

- Complete freedom from maintenance: Freedom from maintenance also plays a major role in the selection of the right high helix thread system. The beer lift should function smoothly for years instead of being regularly lubricated and maintained.

Convincing performance of dryspin high helix thread in beer lifts

The dryspin lead screw technology meets both requirements with the utmost ease. With specifications and shapes matching the polymer nut and lead screw, dryspin provides an even longer service life and more efficiency for high helix threads than the commonly available high helix thread. The lead screw nuts are made of iglidur high-performance polymers, therefore, the entire application is completely lubrication-free and maintenance-free.

The perfect thread system for your beer lift is composed as follows:

1X 1 METRE DRYSPIN HIGH HELIX LEAD SCREW DST-LS-10X25-R-ES

1X DRYSPIN CYLINDRICAL LEAD SCREW NUT DST-JSRM-2220DS10X25

Discover in the online shop:

Test first? No problem!

We will gladly send you a free sample of our dryspin technology. With the sample you get all relevant information at a glance. Request a free sample here.

dryspin technology

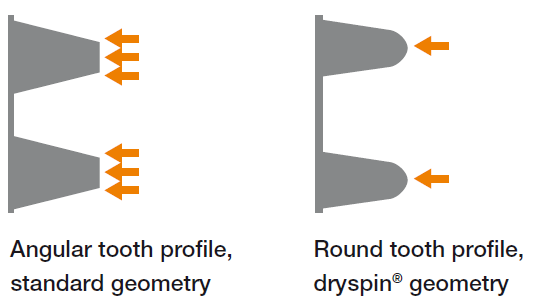

The patented dryspin high helix thread technology was developed by igus in 2015 and offers numerous advantages compared to conventional high helix threads. Due to the flat thread angle, they convert the exerted power efficiently into a translational movement. With properties and shapes matching the polymer nut and lead screw, dryspin thereby provides an even longer service life and more efficiency for high helix threads. Due to the rounded tooth geometry, the contact area between lead screw and nut is reduced, and the lead systems operate quietly and without vibration under load.

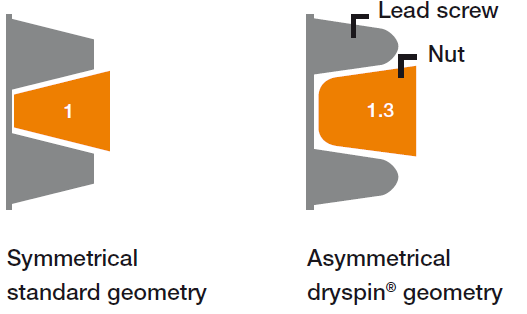

The larger spaces between the individual dryspin threads result in a higher share (factor 1.3) of tribologically optimised polymer in the threads. More wear-resistant material and higher levels of efficiency are crucial for a service life that is up to five times longer compared to conventional high helix threads.

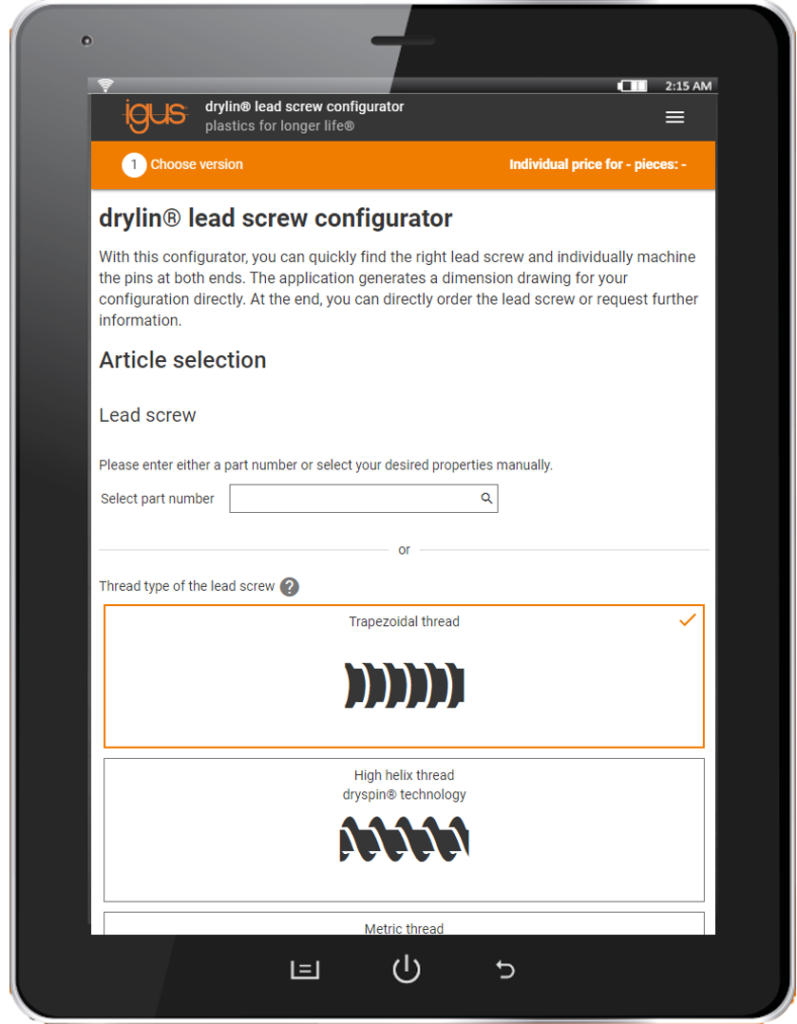

Take advantage of our “machining service“– we manufacture ready-to-fit lead screws based on your requirements. For this, use our lead screw configurator or send us a drawing. We will then provide a quotation.

dryspin technology

The patented dryspin high helix thread technology was developed by igus in 2015 and offers numerous advantages compared to conventional high helix threads.

Due to the flat thread angle, they convert the exerted power efficiently into a translational movement.

With properties and shapes matching the polymer nut and lead screw, dryspin thereby provides an even longer service life and more efficiency for high helix threads. Due to the rounded tooth geometry, the contact area between lead screw and nut is reduced, and the lead systems operate quietly and without vibration under load.

The larger spaces between the individual dryspin threads result in a higher share (factor 1.3) of tribologically optimised polymer in the threads. More wear-resistant material and higher levels of efficiency are crucial for a service life that is up to five times longer compared to conventional high helix threads.

Take advantage of our “machining service“– we manufacture ready-to-fit lead screws based on your requirements. For this, use our lead screw configurator or send us a drawing. We will then provide a quotation.

For more information, please contact us

Kevin Huang

Tel. 021-8036 6699

M.P. 13816366092

khuang@igus.net