Why auto customers trust in the DryLin linear guide products?

Lynna Liu (刘银) | September 10, 2020

Why auto customers trust in the DryLin linear guide products?

With the advantages of free of lubrication, lighter than metal materials, quiet operation and fast delivery, we have attracted a lot of customers in the auto industry for many years, in this article you will find the answers of this question.

What is DryLin?

DryLin® is a unified brand registered by igus GmbH for the linear rolling bearing, the guide and the drive products in dry operation. Different from the traditional rolling linear system, the linear elements in DryLin® rolling linear system is made of iglidur® engineering plastic materials with high performance, which is self-lubricating and free of maintenance, so that it could avoid the grease pollution, so as to keep smooth operation in the dust environment. Meanwhile, the operation is quiet without the limitation of the minimum stroke.

Introduction video of the DryLin® products

Application cases in autos:

Central control armrest

Leg rest

RV lift bed

sliding door

Central control armrest

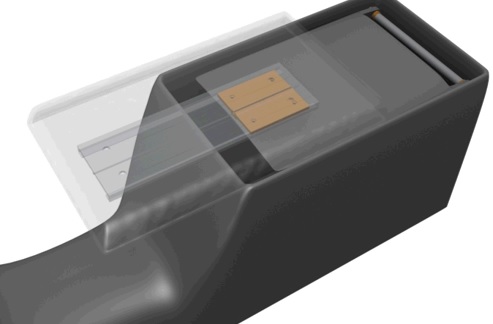

Battery tray guide

Rotation and lifting of the display screen

Compartment extension

Cup holder

Sunshade guide

TV lifting

Front and rear movement of the dining-table

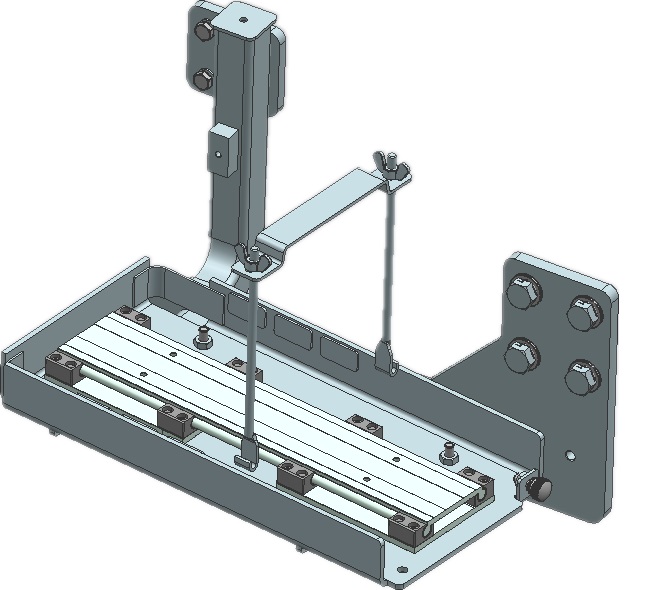

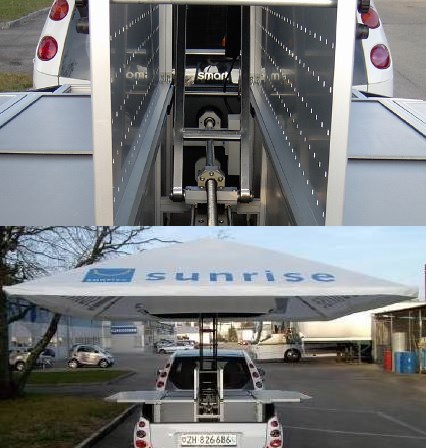

Driving mechanism of the sunshade umbrellas in modified cars

Production series of DryLin® include: DryLin® W-shaped guide, DryLin® N-shaped guide, DryLin® T-shaped guide, DryLin® R-shaped guide, DryLin® Q-shaped guide, DryLin® NT-shaped guide, DryLin® SHT linear platform, DryLin® SHTP linear platform, DryLin® SLW compact linear platform, DryLin® SAW linear platform, DryLin® SLT linear platform with low installation height, DryLin® SLN miniature linear platform, DryLin® SLNV rhombus module, DryLin® SET fast guide screw, DryLin® ZLW synchronous belt drive mechanism and DryLin® ZLN synchronous belt module of low cost.

The linear drive mechanism of the DryLin® E with a motor is an extension of DryLin® drive technology with optional synchronous belt or the dryspin® lead screw drive actuating element. Expect the manually adjusted accessories (handwheel and position indicator), the DryLin® E system with a hybrid stepping motor, DC motor, sensor, DryLin®dryve controller and chainflex® motor cables has more abundant functions and is smarter.

Why using DryLin® in automobile?

Reason 1: light weight

As the plastics replace the metals, the weight has been reduced for 7 times, and the reduction of consumed fuel means the reduction of carbon dioxide emissions. Environmental benefits are the reasons why so many engineers and terminal customers trust our products.

Reason 2: low noise

Compared with the traditional internal combustion engines, it will be particularly obvious in case of any noise in the cockpit of the quiet new energy automobiles. The quiet operation and shock absorption characteristics of DryLin® linear guide are the important reasons for customers to choose IGUS.

Reason 3: reasonable price

A linear ball bearing has many more components than a sliding bearing. Compared with the metal processing, the energy consumption and the cost in manufacturing process of plastics injection molding are lower. Due to the solid lubricant distributed unevenly in the polymer, the machine oil or grease for lubrication is no longer necessary, nor is refuel within the specified maintenance interval.

Less components, cheaper manufacturing process and less maintenance make the linear guide of the plastic sliding bearing 40% cheaper than a similar metal bearing.

Reason 4: free of lubrication

Especially for the automotive interior trim, free of lubrication is always a decisive factor for customers to turn to IGUS from a metal bearing. In the past, lubrication is required to be added to the metal bearing, the dirt in fit clearance adheres to the bearing, and the grease will be harden, blocked or volatilized after a long time. While the Drylin® linear guide does not require any extra grease or lubricating oil at all, and polytetrafluoroethylene, graphite and other lubricating materials have been uniformly applied in the bearing materials to ensure the driving force with the minimum friction coefficient.

Reason 5: sufficient stock

No matter for armrests or linear sunroofs, central control, drawers, seat adjustment or other linear applications, customers can directly find the alternatives of the original metal linear guide in IGUS. IGUS also provides large range of sizes of the standard guides, drives, fast screws and others for the procurement engineers and designers. In case of the insufficient quantity, we can dispatch the products within 24 – 48 hours.

For some products with special geometrical shape or small quantity, we can even produce them by 3D printing. We manufacture such products with optimized iglidur friction performance and deliver within 3 days.

Reason 6: online configuration

The online configurator can provide self-service selection service for customers, in which the guide, main shaft, and the bearing can be easily configured. The service life can be calculated in few steps online, and then the customer can place an order. IGUS tests the materials’ performances through its biggest testing laboratory in the world with more than 15,000 tests in every year, to determine the tribological data and the service life, and integrate them in the online configurator, so as to calculate the most accurate service life by customers. This means that customers can quickly find the cheapest bearing materials under the specific working conditions.

The sellers can use the online configurator to quickly make a visual design scheme, which cannot be replaced by speaking through phones or drawing the sketch face to face, especially when the customers have special requirements of some positions, tolerances and materials, we can discuss on the configurator.

Reason 7: ordering the complex and special parts

For the components beyond our existing standards of sizes, or with the requirement of fast delivery, our 3D printing, injection molding and other processes can make varieties of special designs, which give the designers a great deal of freedom. In the proofing of an automobile, we can quickly produce the first sample no matter in additive manufacturing or bar sheet finished product processing. After verification, the customers have more confidence to start the mold development process in mass production.

In conclusion, the advantages of igus are:

· Fast delivery, the standard parts of the product sample can be fast delivered within 24 hours

· Flexible production benefiting from various manufacturing processes, even the complex components can be produced

· No minimum order quantity

· Online self-service configurator or free consultation offered by the IGUS experts

· Light weight, low noise and free of lubrication

· Optimal linear components

· Lower costs

Contact us if you are interested in the applications of DryLin® in automobiles:

Lynna Liu / 刘银

tel:021-80366201

email:lyliu@igus.net