automotive electronic thermostat bearing ——iglidur® H1

Lynna Liu (刘银) | June 28, 2020

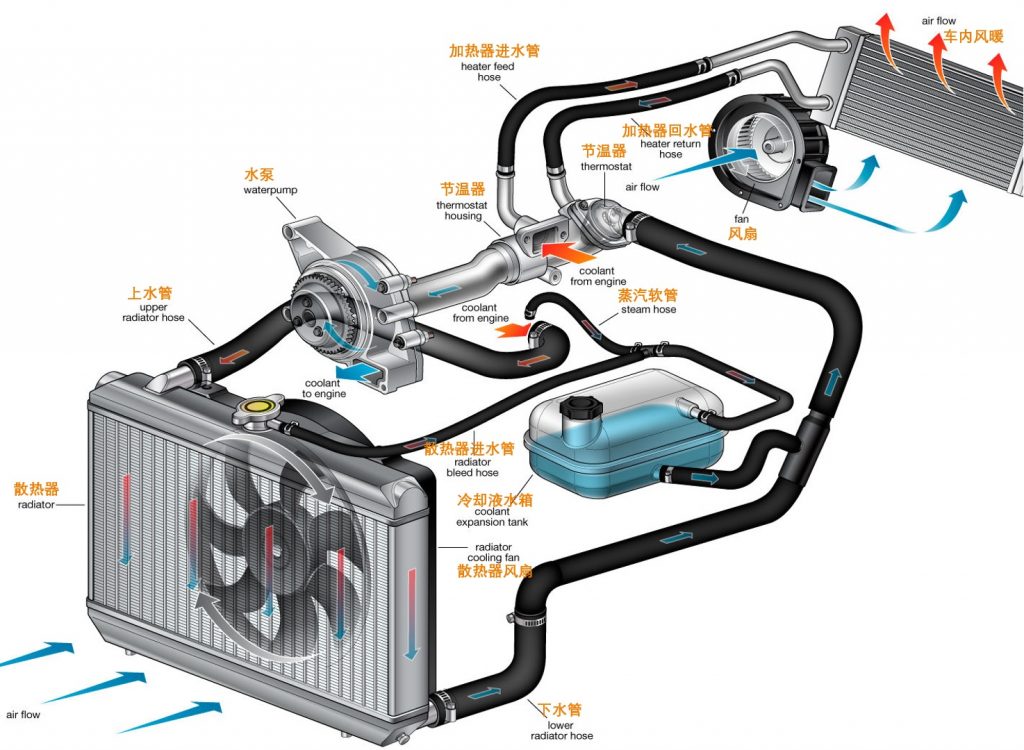

The automotive thermostat is a valve that controls the flow of engine coolant, whose temperature can neither be too high nor too low. The thermostat can automatically adjust the amount of water entering the radiator according to the temperature of the coolant to keep it at the optimal working temperature, which is important for the service life and efficiency of the engine.

When the vehicle is started and the temperature is relatively low, the thermostat automatically closes the path to the radiator and opens the one to the pump, and the coolant is circulated in a small cycle, which can speed up the heating and let the engine reach the optimal operating temperature as soon as possible. As the temperature rises, the thermostat adjusts the opening degree so that part of the water enters the radiator, and slows down the rising of the temperature. At this time, large and small cycles exist simultaneously. When the temperature exceeds the optimal working temperature, the thermostat opens completely and the coolant flows back to the engine through the radiator and the thermostat valve, and then through the water pump, in which way a so-called large cycle of coolant begins, so as to ensure the optimal temperature of the antifreeze in the engine.

Automotive Thermal Management System

If the thermostat is damaged, the valve will remain closed or open, and the engine will always be in a high or low temperature state. When the temperature is too high, the charging efficiency and the engine power is reduced. The engine tends to pre-ignite and deflagrate and the parts will be damaged prematurely, deteriorating the lubrication between moving parts, and exacerbating the wear. When the temperature is too low, the ignition is difficult or too slow, lowering down the engine power. Also, the oil viscosity increases, thus augmenting the resistance between moving parts. Therefore, to ensure the service life of the engine, the temperature can neither be too high nor to low.

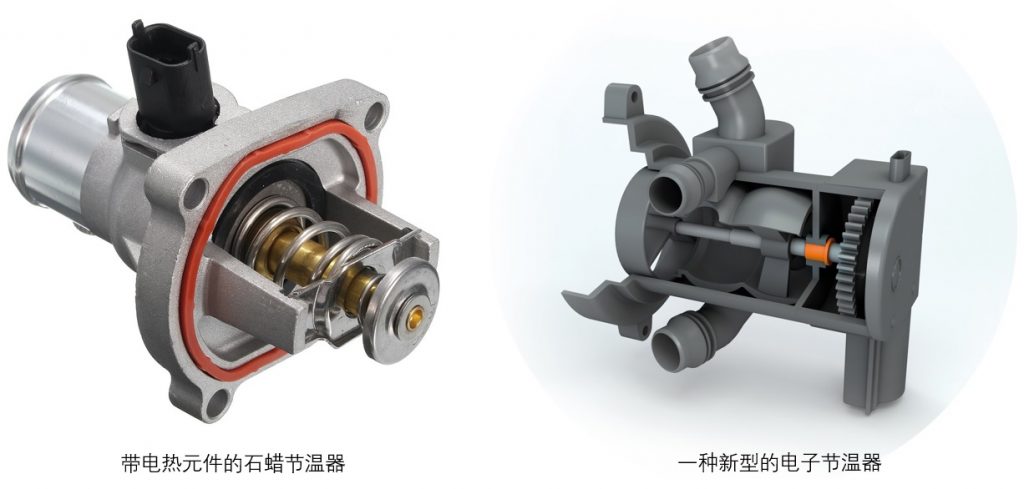

The traditional thermostat opens the valve through the volume expansion of the paraffin, when it changes from solid to liquid. At present, there is a product commonly known as “electronic thermostat”, which is mechanical paraffin thermostat with electric heating elements added on. When the cold car is under heavy load, the electronic part heats the paraffin and let the thermostat valve open in advance. According to this valve action principle, this “electronic thermostat” is still mechanical. The electronic thermostat mentioned in this article is the one that transmits the resistance change signal of the thermistor to the ECU of the engine, and uses the electronic actuator to open the valve. Compared with the paraffin one, the housing and valve action part of this new type electronic thermostat are made of high temperature resistant polymer materials, which not only reduces the weight, but also avoids rust and corrosion. The preset optimal temperature is not limited by the paraffin melting point, which makes the cooling system more agile and intelligent.

paraffin thermostat & electronic thermostat

In the valve shaft position of the latest generation of mass-produced electronic thermostats, why do we choose iglidur H1 as bearing material?

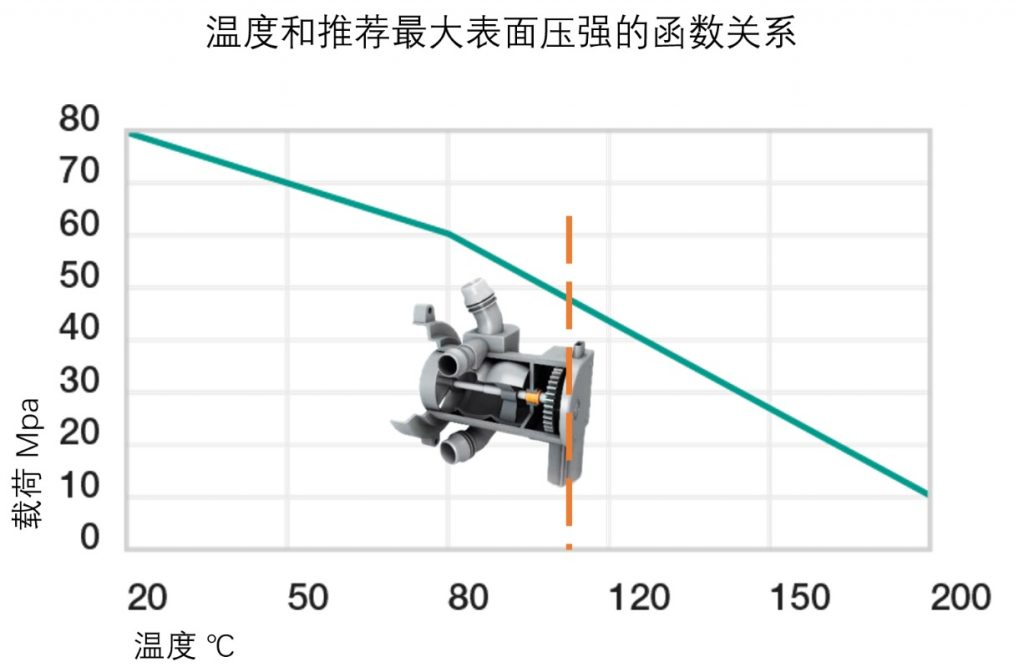

1. High temperature resistance

The iglidur H1 material has a temperature resistance of 200°C and can even withstand 240°C in the short term. Even if the engine coolant temperature reaches the boiling point, which is usually 110℃ above zero, the iglidur H1 bearings can still withstand a load of more than 45Mpa, ensuring the operational reliability under complex fluid pressure environment.

2. Very low water absorption

Under standard atmospheric pressure, 23°C and 50% relative humidity, the water absorption of iglidur H1 plain bearings is 0.1%, and the saturated water absorption when fully immersed in water is only 0.3%, which makes it one of the materials with the lowest water absorption in the iglidur series.

3. Very low friction coefficient at high temperatures

The advantage of iglidur H1 plain bearing material is that even if the bearing is exposed to high temperature and corrosive chemicals, it still has extremely high wear resistance and excellent friction coefficient. For example, the friction coefficient against the rigid shaft in water environment can reach 0.04.

4. High chemical resistance

All H series have strong chemical resistance, and can maintain performance and dimensional stability in pure alcohol, glycerin, and ethylene glycol coolants.

5. Cost-effective

Compared with ceramic or graphite bearings, iglidur® plain bearings have a strong cost advantage.

If you have similar application requirements, please don’t hesitate to contact me:

刘银/Lynna Liu

tel:021-80366201

Email:lyliu@igus.net