3D printing: low-wear plastic components for the automotive industry

Martin Liu | March 29, 2020

Design freedom and fast reaction

times are commonplace in development departments in the automotive industry.

Anyone who can react quickly to new requirements gains competitive

advantages.

Additive manufacturing and the automotive industry, which benefits from

flexibility and speed, are made for each other. Free design possibilities,

short delivery times and cost efficiency are only a few reasons why suppliers

and OEMs use 3D printing more and more often.

iglidur® high-performance plastics ensure smooth movement in the automobile

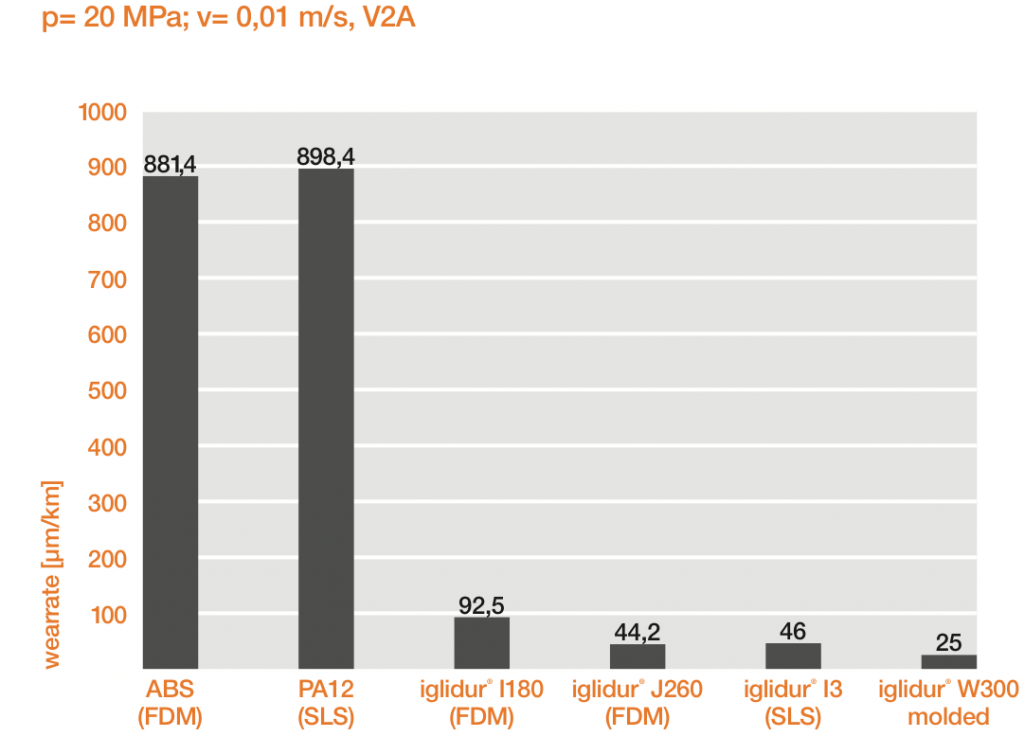

In particular for components in moving applications, the focus is on low friction, noise reduction and durability. As market leader, igus concentrates on developing and using tribologically optimised plastics, also within manufacturing with 3D printing.

Additive manufacturing uses standard materials, such as ABS and PA12. Applying iglidur high-performance polymers results in entirely new application areas. That way, noise-sensitive applications inside motor vehicles, such as sliding elements at the steering wheel, are realised with readily available and cost-efficient printed special parts by igus. The goal is to increase service life of the applications while ensuring freedom from maintenance and lubrication.

3D printing also for high-volume production?

Durability and quality are the important keywords. Components printed in 3D can and should be not only tested, but also used in high volumes in highly demanding automobile applications, such as turbochargers. That is our aspiration.

Printed parts tested in the industry’s largest test lab

Quality standards and

requirements of the automotive industry are high. The components are produced

additively from iglidur materials and have to compete with the parts produced

with conventional methods.

What is the point of a fast and cost-effective solution, if it fails at an

early stage? For us, printed parts for illustrative purposes only are a thing

of the past; therefore, igus puts the parts to the acid test to ensure their

resistance.

More than 15,000 tests of parts and materials every year – application-oriented in the in-house test lab, which is the largest in the industry with an area of 3,800m². The obtained data are incorporated in the material development of new iglidur plastics and also in the online service life calculator . Here, after entering parameters such as part size and speed, the realistic service life of the own application is calculated.

Short delivery times in 3D printing?

By using online tools such as the 3D printing service, the delivery time is decreased: upload the 3D model of the part as CAD file into the iglidur Designer, select iglidur material and quantity, find out price and order. The parts can be used after only three days.

Tested quality: 3D printing solutions for the automotive industry

The by now countless possibilities for manufacturing individual special parts within very short time are impressive. Due to the different methods in 3D printing, we can react very precisely to the individual requirements regarding the parts.

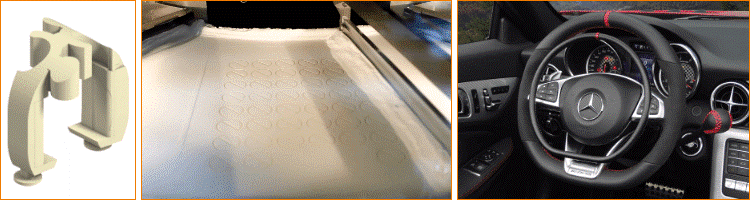

Produced with the SLS method: special parts for steering wheel accelerator ring

The company Kempf develops and markets

high-quality special solutions for drivers with handicap. The company

offers a 30-year guarantee. Therefore, requirements regarding the used parts

are high. “Darios 211”, the model name of the digital accelerator ring, enables

a driver who cannot use his legs to accelerate with the hands on the wheel. In

the accelerator ring, Kempf installs over 200 identical special sliders, which

are produced with 3D printing and made of iglidur® I3. This material’s special

feature is its freedom from lubrication and maintenance.

We at Kempf have opted for additive manufacturing. A great advantage is the

maximum design freedom. Customer requirements can be realised individually.

This saves both time and money. With injection moulding, producing the part would

result in very high tool costs.

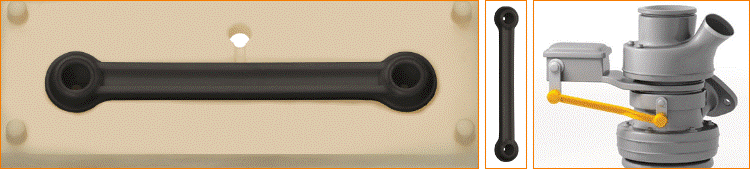

Realised with the print2mold method: coupling joint for turbocharger

A manufacturer of turbochargers requires a suitable special part as quickly as possible. Challenges are the short reaction time and an application temperature of over 200°C. Within ten days, the toll was constructed and printed with the SLA method; after 14 days, the client was able to test the iglidur® coupling joint successfully.

Produced with the SLS method and shipped within three days: printed gear for side door actuator

The client uses lubricated plastic bearings. Lubricators that melt under the influence of temperature damage the drive. Within three days, we sent our lubrication-free igus solution to the client.

PS: whether plain bearings, spherical bearings, linear bearings, special sliders, gear or individually customised geometry, the iglidur® Designer leaves nothing to be desired.