Stainless steel linear modules in drive technology

Kevin Huang | March 10, 2022

Where are stainless steel linear modules used, and what advantages do they have?

Not all stainless steels are the same

There are two types of stainless steel that are used in linear drive technology. There is X46/X90 stainless steel and V2A/V4A stainless steel. X46/X90 is a hardened stainless steel material, while V2A/V4A is not hardened.

Hardened V2A stainless steel

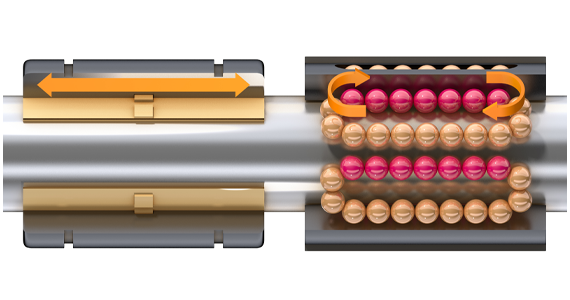

Linear modules and linear axis guides of hardened stainless steel are usually offered in combination with recirculating ball bearing systems and roller bearing guides. The guide system’s metal balls require a strong running surface to prevent them from creating grooves. Hardened stainless steel such as 1.4034, 1.4112, and 1.4125 has a relatively high carbon content (more than 0.5%), which is necessary for hardening in the first place. This means that hardened stainless steel is only somewhat corrosion-resistant. The necessary lubrication for recirculating ball bearing systems and roller bearing guides entails a danger of contaminating products, which is undesirable in many areas.

Non-hardened V4A stainless steel

Non-hardened stainless steel has a lower carbon content and inferior hardness, but is much more resistant to corrosion and aggressive cleaning agents and chemicals. Because recirculating ball bearing systems and roller bearing guides are not as well suited to moving on non-hardened stainless steel, a plain bearing system is used. The force exerted at particular points on the rail material is changed to area force. The load on the linear rail is distributed across a greater area, avoiding material wear.

The principle: “sliding instead of rolling”

The advantages of plain bearing liners over a recirculating ball bearing system

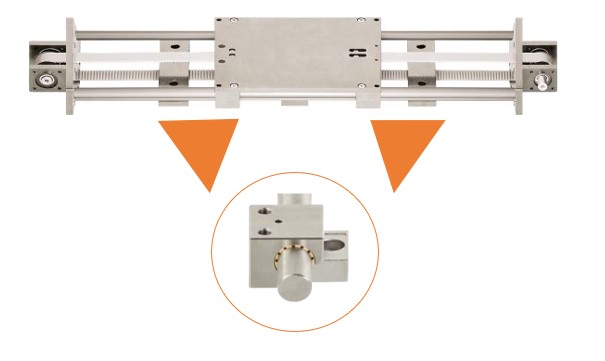

The high-performance polymer plain bearing liners used by igus need no lubrication or maintenance and are ideal partners for stainless steel linear modules. The combination of plain bearing system and stainless steel linear axis is used in certain applications because of the advantages of linear drive systems.

Stainless steel linear modules in application

Wherever lubrication must be dispensed with and machine components contact food, strong cleaning agents, or even chemicals, stainless steel is necessary. To minimise maintenance and cleaning effort, igus has developed linear modules and linear axes for just this scenario – drylin E linear modules made of stainless steel.

Frequent use of stainless steel linear modules with plain bearing systems:

- Chemical industry

- Pharmaceutical industry

- Food industry

The advantages of igus stainless steel linear guides with plain bearing systems

- Maintenance-free due to self-lubricating high-performance polymers

- Corrosion-free due to V2A (AISI 304) and V4A (AISI316/316TI) stainless steel

- Great resistance to chemicals and cleaning agents

- Can be configured with drylin E stepper, DC, and EC/BLDC motors

- D1 dryve motor control system available for delivery