Maintenance of plain bearings … Is maintenance-free the same as dry operation?

Yvan Cao | November 11, 2020

Maintenance is a central point when operating machines.

On the one hand, this ensures operational safety. On the other hand, maintenance is associated with expenditure.

This expenditure is divided up as follows:

The machine is at a standstill during maintenance. Depending on the machine, this is expensive. A construction machine cannot be rented.

And problematic depending on the field of application … clouds on the horizon and the harvesting machine has to be lubricated first. This calls for very good nerves.

Costs for necessary material. If a large construction machine or a sowing machine with many rows is lubricated, the costs for the grease alone are quite considerable.

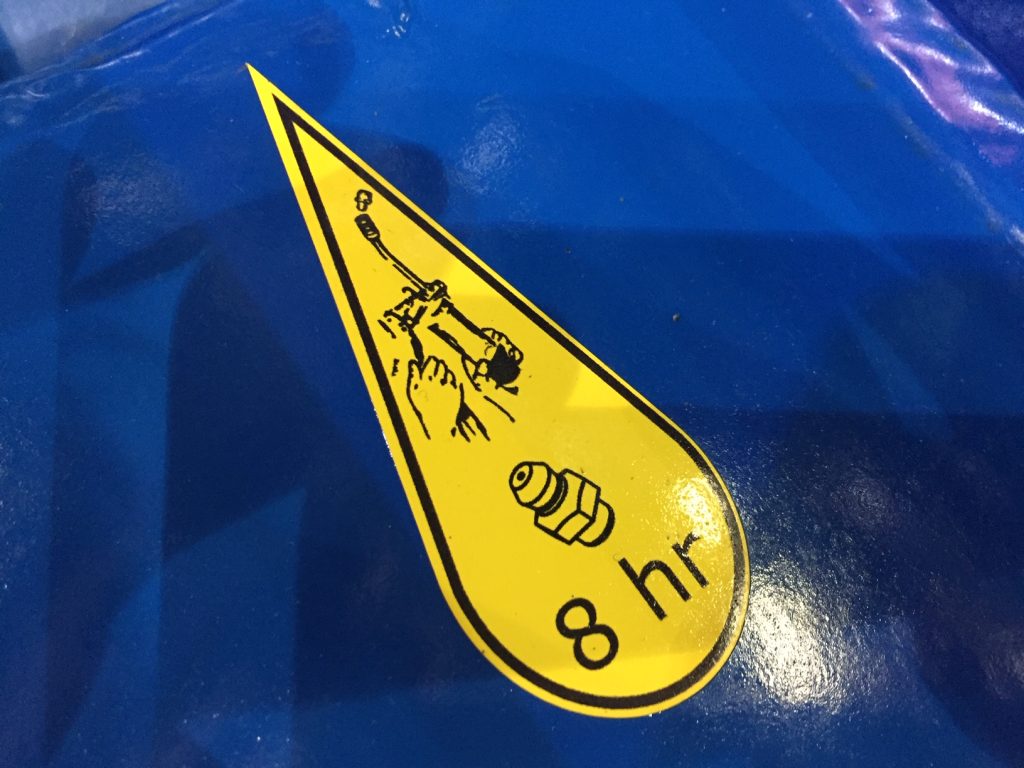

At work … at the edge of the field, just a little maintenance under precarious conditions and a tub of grease (source: own production)

Costs for the necessary manpower.With a large telescopic crane, one reckons half a day for two experienced mechanics. Even on a sowing machine this can quickly add up due to the many lubrication points … And if a few grease nipples no longer co-operate, all the more unpleasant.

And if we don’t do the maintenance?

Then machine failures can occur with considerable consequences.

Then a little grease won’t help.

Then it is quickly time for a complete overhaul of the bearing point.

Then it was probably too late.

If the bearing is completely worn, the shaft runs in the mounting. Just to get the bearing seat of a wheel loader in the gravel pit “in shape” again, no one would want to experience this, the mere idea is enough to cause more discomfort.

So, always lubricate well according to the principle “a lot helps a lot”.

However, if maintenance intervals are long and can therefore be planned, the machine can be lubricated when a standstill is less disturbing (after the harvest is in the barn). “Predictive maintenance”

But does the specification look like this:

Every eight hours… please, not during harvest. (Source: own production)

Then it gets stuck … so get out of the cabin, put the grease gun in your hand and get to work.

It is a fact that the typical metallic plain bearings must be lubricated in order to function as a system. Grease is a part of the system.

Metallic plain bearing + grease + shaft = bearing system

The iglidur plain bearings, on the other hand, are self-lubricating; the addition of grease is not necessary.

The “formula” is accordingly shorter:

iglidur plain bearing + shaft = bearing system

So, all clear for now. In the system iglidur plain bearing + shaft lubrication and the associated maintenance is not necessary. No effort, no downtime, no machine failure, no collateral damage.

The note could then look like this:

No need to lubricate – that feels good! (Source: own production)

Since, in practice, neither the shaft nor the mounting are usually protected against corrosion, the absence of grease could possibly lead to corrosion problems. In this case some grease should be applied “from time to time”. Not to service the bearing, only to ensure corrosion protection.

Details on this point are covered here:

In any case, maintenance intervals can be stretched far apart and can be better planned. For applications in the agricultural sector, the beginning or end of the season is a good choice.

Under certain circumstances even a one-time lubrication (assembly lubrication / initial lubrication) can be sufficient for the entire service life.