GJRM——Heavy-duty thread

Kevin Huang | September 22, 2020

Can the heavy load be combined with threads?

What are the advantages of threads in heavy-duty applications?

When threads are used in heavy-duty applications, they must meet many requirements. One of the most important aspects for heavy loads is the stability of the threads under high axial and radial loads. But does this also work with lead screw nuts made of polymer?

Clear answer: Yes! The drylin lead screw technology development team has set itself the task of developing a robust alternative to the flange lead screw nut. The special type of the lead screw nut plays a decisive role here. We will go into this in more detail later on. In addition to the innovative design, the high-performance polymer iglidur J contributes to a wear-optimised, lubrication-free and maintenance-free application, as is usual at igus.

The heavy-duty thread

Advantages of the type

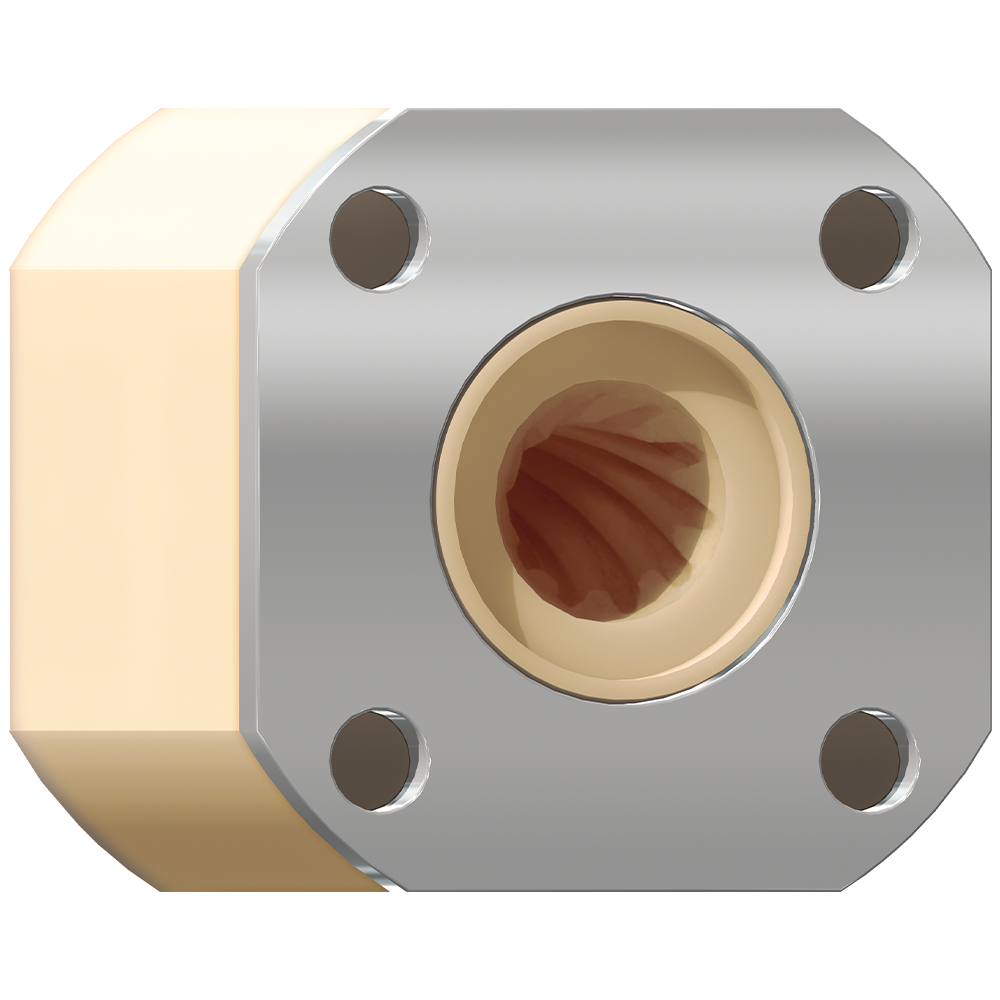

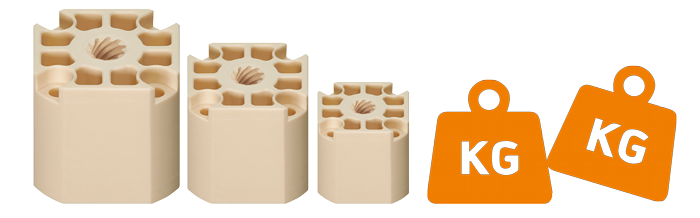

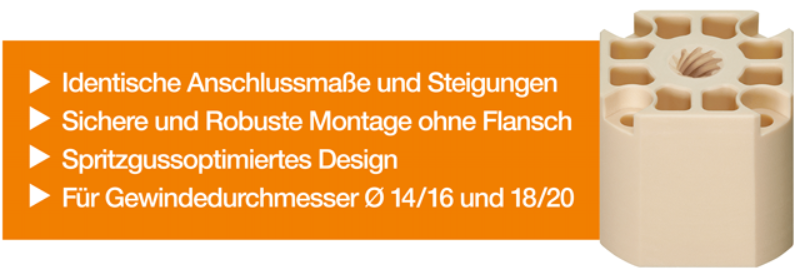

The new lead screw nut for heavy-duty applications is characterised, amongst other things, by its identical connection sizes and pitches for commercially available ball screws. A real alternative especially in combination with the patented dryspin lead screw technology, also in the new dryspin dimensions such as Ds16x10 and Ds20x5. Due to its design optimised for injection moulding, the new polymer lead screw nut can be used instead of metal and offers all the advantages of using iglidur high-performance materials. A robust and safe mounting without additional flange is possible. The thread centring spigot, the anti-rotation feature by means of spanner flats and the use of four M6 cap head screws help in assembling the lead screw nut very easily.

But probably the most decisive advantage of the special type is the absorption of high axial loads. Compared to a ball screw drive, a thread system consisting of JGRM lead screw nut and igus lead screw can also compensate well for the occurrence of radial loads. The new lead screw nut is already available in DS16x5 and Ds20x10 dimensions, which are 1 to 1 interchangeable with the ball thread. Due to the patented dryspin asymmetry, long-lasting use is guaranteed.

The heavy-load threads as heavy-duty version

To be able to withstand even higher static axial loads, the new lead screw nut is also available in a heavy-duty version. This heavy-duty lead screw nut can withstand up to 30% higher static axial loads compared to other versions with identical threads.

For this purpose a stainless steel plate is mounted in front of the heavy-duty lead screw nut. The flange size of the lead screw nuts remains identical. Withstand loads up to 6MPa. Due to the stainless steel plate, the contact surface for force dissipation is enlarged as the screw heads no longer come into contact with the polymer but on the stainless steel plate and the entire upper surface. This version withstands axial loads up to 6MPa. The heavy-duty lead screw nut is perfect for applications with very high static loads that are not very dynamic, e.g. format adjustment.

Installation of the heavy-duty thread

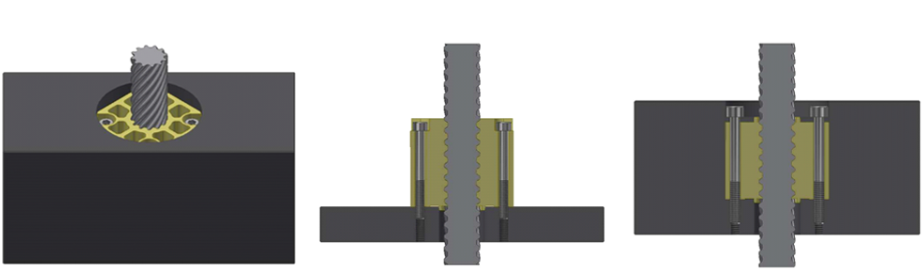

The lead screw nut can be installed in a variety of ways. One possibility is to fix it on the component, and another is to mount the lead screw nut in the component.

A thread centring spigot and four M6 cap head screws ensure easy installation and secure screw connection. They help the lead screw nut to absorb the high radial loads and ensure vibration-free application.

Summary:

The JGRM lead screw nut is a robust and cost-effective alternative to conventional ball screws. It is characterised by its high stability under axial and particularly static loads. In addition, the lead screw nut is more forgiving of radial loads than comparable ball screw units. The variability during assembly is a great benefit of the JGRM lead screw nut. The heavy-duty lead screw nut accessory provides up to 30% more absorption of axial loads. The use of injection moulded blanks has the advantage that the lead screw nut is cost-effective and variable. It is initially available in two installation sizes, each for the thread diameters Ø 14/16 and 18/20.

Our experts will of course be happy to advise you in detail: Go to the contact form.

Tech up

- New lead screw nut design makes it easy to fix securely

- Connection sizes identical to conventional ball screws

- Robust, secure frontal mounting without flange

- Available as heavy-duty version with metal plate for high static axial loads

Cost down

- Cost-effective type, optimised for injection moulding

- Variable design for all thread sizes Ø 14/16 and 18/20

- Alternative to metallic ball screw nuts

Proof

- Easy installation due to thread centring spigot and four M6 cap head screws

- Service life can be calculated online

- The heavy-duty version can cope with 30% higher static axial loads than flange lead screw nuts with the same threads

Sustainability

- Lightweight and low inertia thanks to polymer instead of metal

- Noise reduction due to rounded thread flanks

- Lubrication-free and maintenance-free operation

- Long-lasting use due to patented asymmetry

- igus supports the circular economy of plastics and is investing in chemical recycling. Learn more about this topic at: www.igus.eu/plastic2oil