Advantages of polymer bearings in the bicycle

John Ji | August 10, 2020

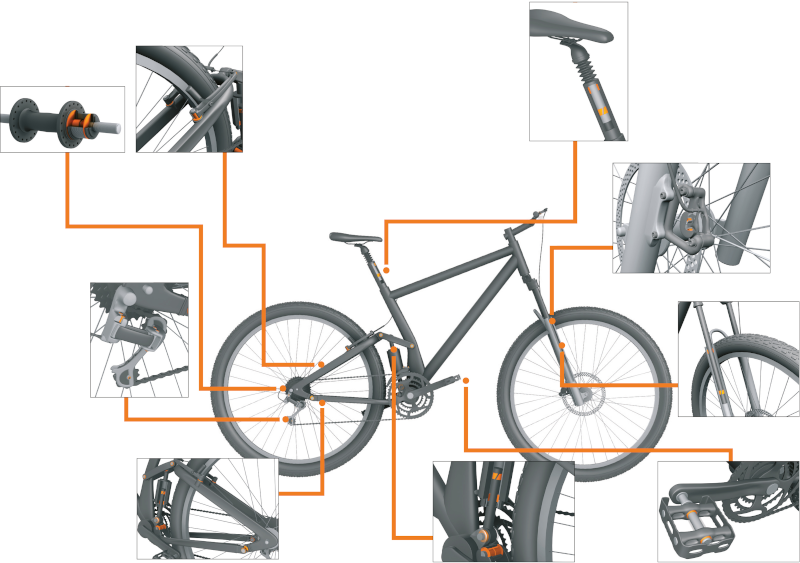

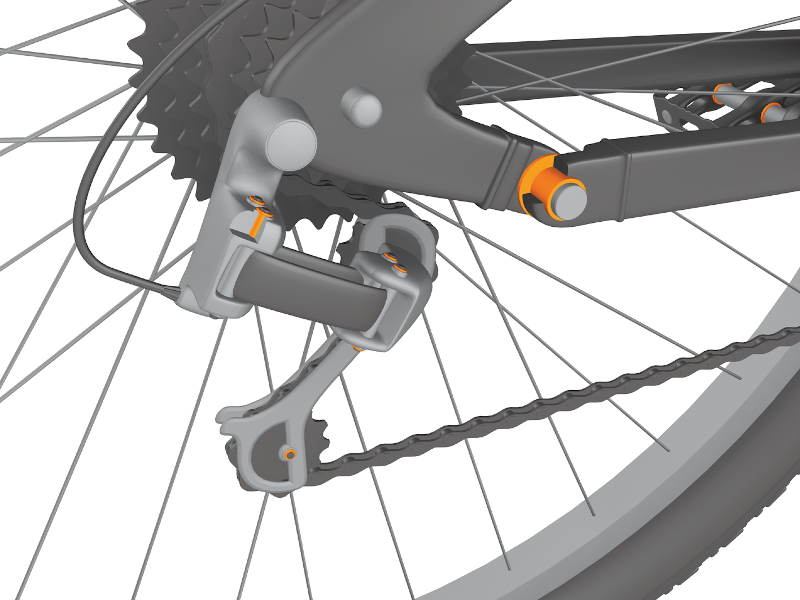

In the bicycle industry, innovative solutions are not only focused on design, but also on the choice of materials. For example, for the frame there are many solutions made of aluminium or glass fibre reinforced material. Component manufacturers are also working flat out on the use of alternative materials. Be it saddle post, suspension, pedals or the gearshift – plastic is becoming increasingly important. Polymer plain bearings in particular are gaining in popularity because they have many advantages over metal plain bearings:

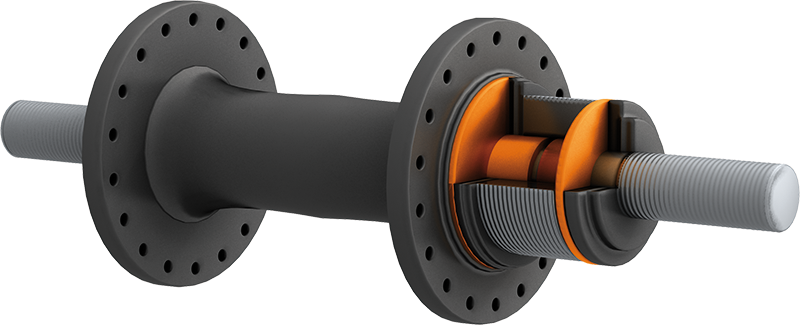

1. Weight

The weight is one of the most important points when buying a bike. In the everyday use of a bicycle, you often encounter problems when lifting the bike, for example, to climb stairs or when loading it onto the luggage rack. Furthermore, weight reduction is a priority in cycling, as every gram is crucial. A polymer plain bearing from igus is about 7 times lighter than a comparable metal plain bearing.

2. Corrosion

A polymer plain bearing is corrosion-free and offers a great advantage in humid areas and when riding in the rain. Especially in the area of mountain biking, where a lot of riding is done in dirty and wet terrain, the humidity gets to the metallic bearing. With tribologically optimised polymer plain bearings, no destructive corrosion occurs.

3. Wear and service life

A further criterion in the selection of materials for the plain bearing is wear and the associated service life. In the case of a metallic plain bearing with a PTFE coating, this is quickly worn out after the ingress of dirt and edge loads and no longer offers adequate sliding properties. The service life of the plain bearing is greatly reduced. In addition, the worn-out anti-friction coating creates metal-to-metal friction, which causes the bearing to creak and generate unpleasant noise. With a polymer plain bearing, on the other hand, the entire wall thickness is used for sliding so a longer service life is achieved, since the additives responsible for lubrication are homogeneously distributed in the material. By the correct selection of the mating surface, wear can be further reduced.

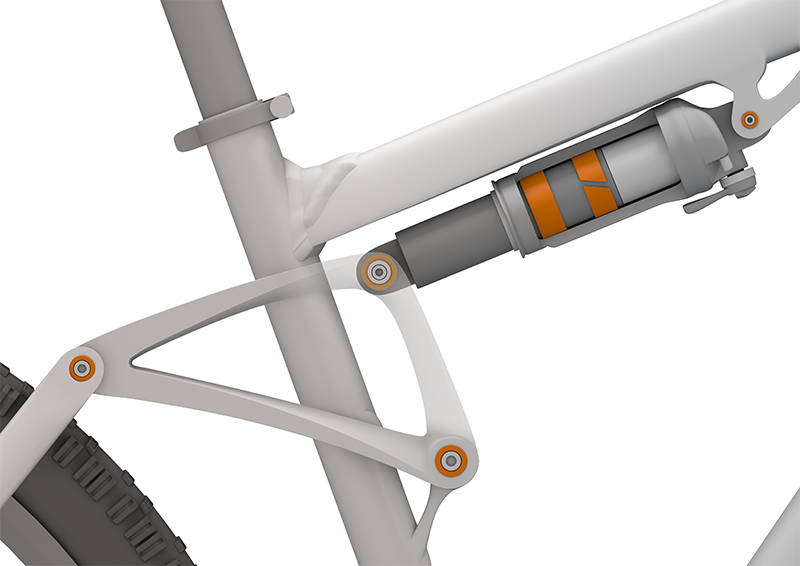

Damping piston-iglidur J

Shock absorber-iglidur J3

seatpost-iglidur J

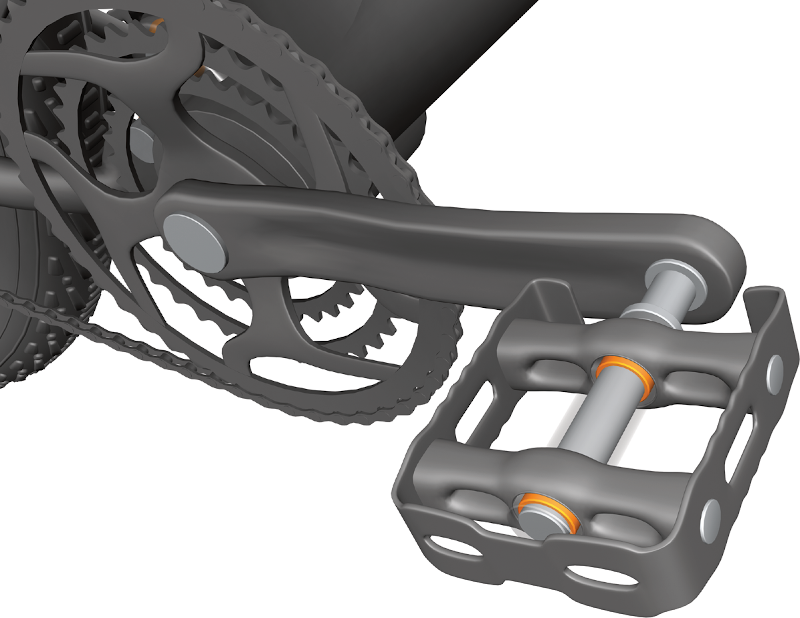

pedal-iglidur J3

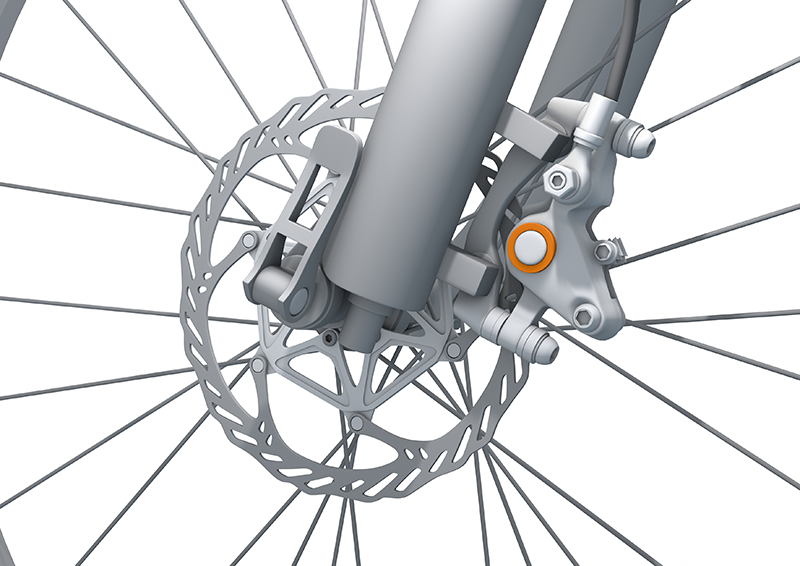

Disc brake-iglidur H

Brake caliper-iglidur J

sprocket-iglidur G

Racing brake-iglidur G

Suspension-iglidur J

A suitable tool for choosing the right iglidur material is the service life calculator from igus, which you can find under the following link: https://www.igus.eu/info/plain-bearings-iglidur-experts

We look forward to your visit to our homepage: https://www.igus.com.cn/info/industries-igus-bike

Or we can discuss the other advantages and possible uses of our tribologically optimised polymer plain bearings in your application in a personal meeting on-site.