New material iglidur® K250 in automotive applications

Lynna Liu (刘银) | July 1, 2020

Thanks to our modern injection molding production process, the desired iglidur® plain bearing can be manufactured in almost any geometry, for example as a flexible iglidur® clip bearing or flanging sleeve especially for quick assembly in sheet metal solutions.

This design is used in hinges and seats in automobiles, and igus is constantly optimizing and developing new materials for these applications. For bushing that suitable for punching, we usually recommend iglidur M250 as the best solution. Now we have a new material——iglidur K250, which not only inherits many advantages of iglidur M250, but also shows more significant advantages in temperature resistance, flexibility, and wear resistance.

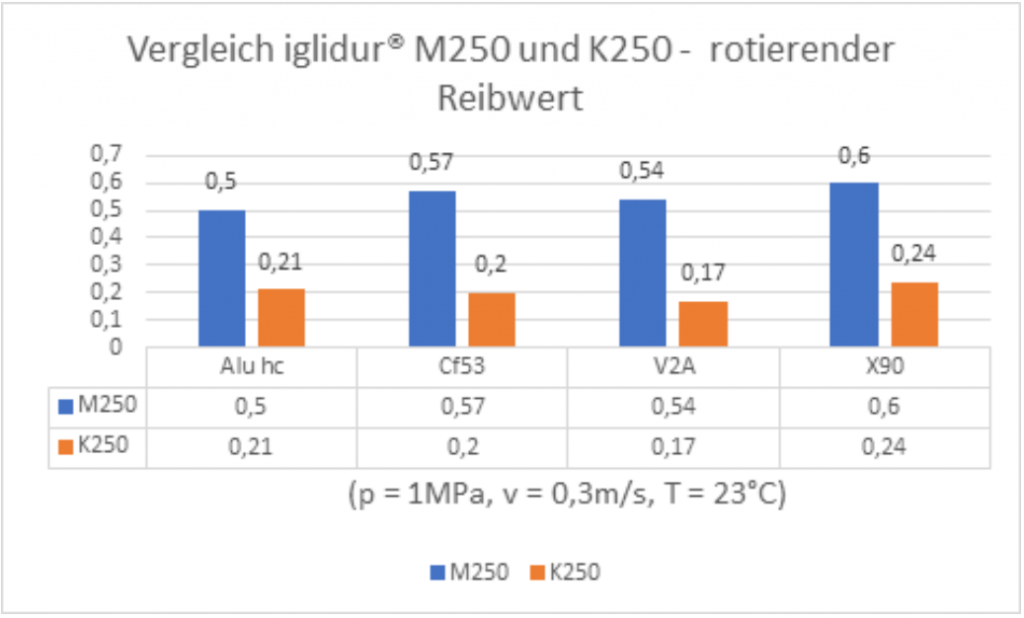

The coefficient of friction of K250 was more than halved for all counter-rotating partners tested.

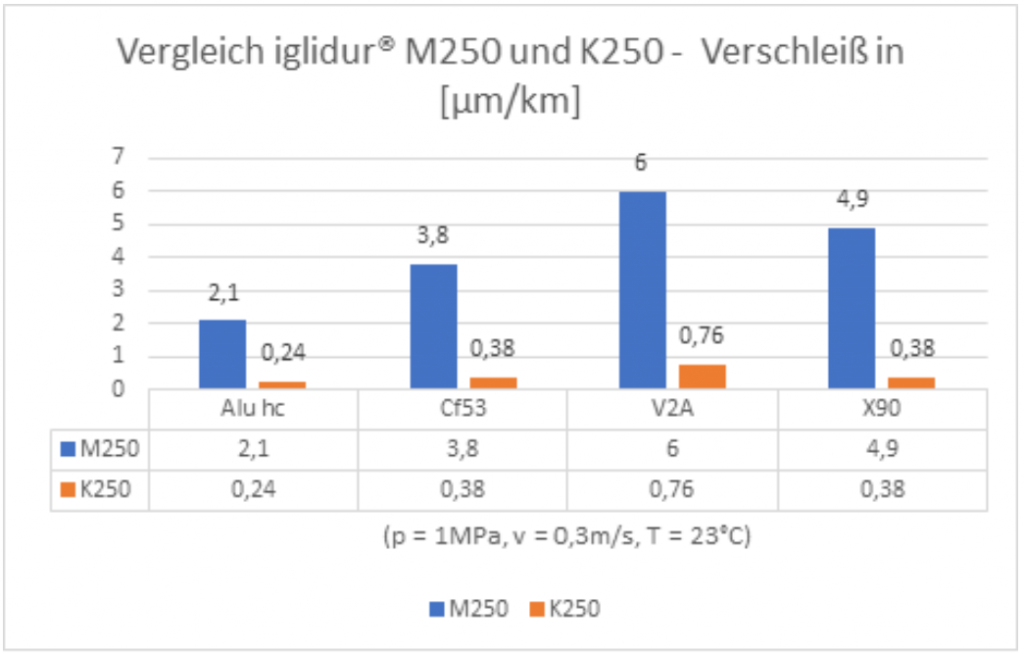

The wear rate in [μm / km] when rotating (for loads, see table) is 10 times lower with K250 compared to M250.

The material retains its flexibility even in extreme cold and dryness and is therefore particularly suitable for flanging or double collar bushings.

We will continue to carry out further tests on our new material iglidur® K250 in the future and keep you up to date.To view existing standard size clip bearings and material performance parameters, please click:https://www.igus.com.cn/product/20278

We would be happy to present you with further advantages for our plastic plain bearings.

刘银/Lynna Liu

tel:021-80366201

email:lyliu@igus.net