How do iglidur plain bearings reduce noise in automobiles (Buzz, Squeak and Rattle)?

Lynna Liu (刘银) | June 23, 2020

In this fast changing time, some technologies may be popularized soon after they are launched. For example, the heat insulation technology is only available for high-end cars a few years ago, but now it was used by almost all cars. When designing storage spaces, quality demand from design and manufacturing engineers increasingly grow. As a result, new technologies and new materials are constantly emerging to meet changing needs. In the case of alternative drives such as the hybrid or electric motor, the noise of the drive is reduced, as a result of which noises inside the vehicle are masked to a much lesser extent by a loud combustion engine. At the same time, it is becoming quieter and quieter inside motor vehicles. To take a seriously looking at automobile noise reduction NVH or BSR, some OEMs have dedicated research team, and igus has often received technical consultation on noise reduction recently, because people always think of plastics when they think of isolating noise between metals. In accordance with the principle of “cost down, life up” , igus automotive experts provide solutions for demanding system suppliers and OEMs worldwide.

What is Buzz, Squeak and Rattle (BSR)?

BSR are all noises that are produced by components and assemblies in the motor vehicle. BSR testing, also called a noise and rattle test, is an acoustic method from the automotive industry and is used to measure the volume of these noises. A realistic situation with corresponding vibrations is simulated and the volume of the noise is then measured. The technical challenge for the vehicle and component engineers is to identify the ‘noisy’ components and replace them with a quieter solution wherever possible.

BSR abnormal sound is directly related to people’s subjective feelings. The noise generated by the engine and transmission system of traditional cars masks the abnormal noise of the body and interior. However, with the popularization of new energy vehicles, the noise of the power system has been greatly reduced, and the abnormal noise of the car-body and interior has been highlighted. It affect the driving experience of people in the car. Therefore, in recent years, the OEMs’ expectations and emphasis on BSR testing have also increased.

How do iglidur plain bearings reduce noise?

Noises always arise where components interact with each other, in other words where friction occurs. Compared with sliding bearings made of metal, plastic has greater elasticity and can absorb shock. With the tribologically optimised high-performance polymers from igus, you achieve an especially low coefficient of friction and therefore a quiet application.

Traditional metal bearings have two methods to reduce noise: adding lubricant and using coated metal bearings. The former often fails due to the evaporation or hardening of grease. The latter’s coating is very sensitive to dust and edge loads. Once there is a little knock, the damage speed will be accelerated, and eventually the noise reduction function will be lost. And igus’ plastic bearings completely avoid these, whether it is a car’s seat, hinges or electric actuators, igus provides a wealth of practical support for this conclusion.

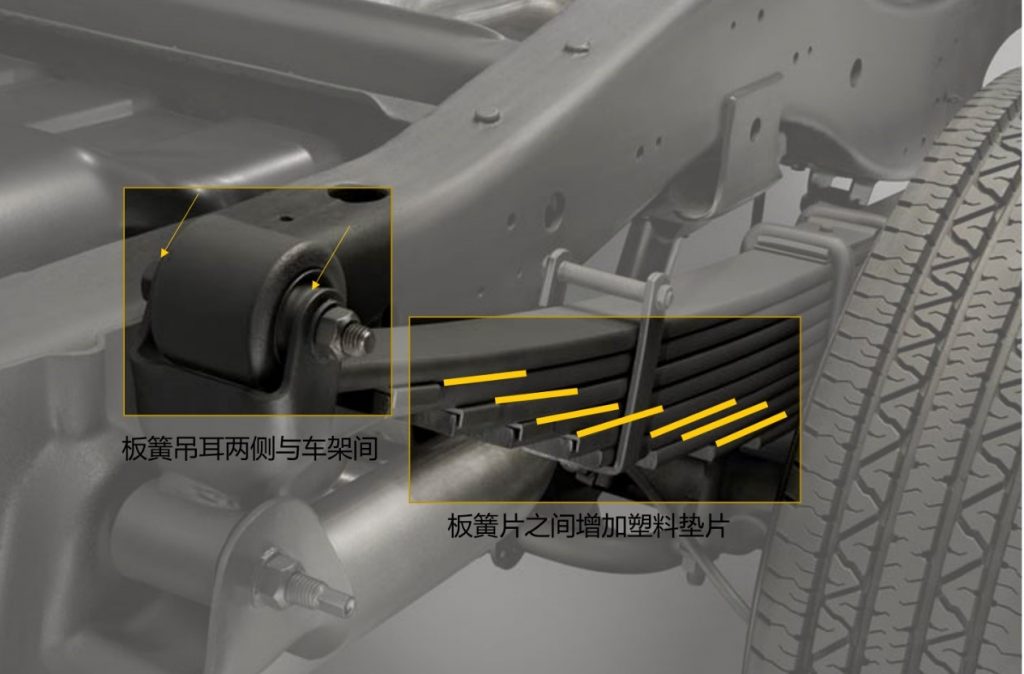

For example, chassis leaf spring noise reduction, the following figure is a schematic diagram of the new energy bus chassis noise reduction, plastic gasket will be added between the lug and the bracket, and also between leaf springs ,to effectively reduce noise.

Reduce BSR of leaf spring

If you happen to have similar noise reduction requirements, please contact me:

刘银/Lynna Liu

电话:021-80366201

邮箱:lyliu@igus.net