Beside controll lever, can we talk about any other applications with FAW truck transimision egineers?

Lynna Liu (刘银) | June 10, 2020

“In 2020, Jiefang aims to sell 170,000 tractors, and seize the market opportunity in the transportation of natural gas, gravel and hazardous chemicals, and AMT tractors.”

“Jiefang will launch 2020 J6L pilot version and Dragon VH upgraded version in 2020”

“By 2020, Jiefang aims to sell 35,000 dump trucks “

“In 2020, Jiefang aims to sell 7,000 J7 “

—- Cited from “CVWORLD” Dec 12, 2019

“Jiefang’s sales surging by 372%, heavy trucks reaching sales of 60,000 in April, and the monthly sales of heavy trucks per company reaching 50,000 units, this is definitely a world record and a miracle of the heavy truck industry. “

“From January to April, Jiefang sold 5,794 medium trucks, with a year-on-year increase of 187%. Among them, J6L and J6K are the main models of medium trucks sold by FAW Jiefang.”

-Cited from “Find” May 15, 2020

FAW Jiefang is China’s first domestically produced commercial vehicle brand and the only commercial vehicle company in China that has mastered the core technologies of world-class complete vehicles and three powertrains. igus GmbH was founded in Germany in 1964, focusing on the field of engineering plastics for 56 years. It established its wholly-owned subsidiary in Shanghai, China in 1999. During the past 20 years, FAW Jiefang and igus have maintained close communication and cooperation. In recent years, Jiefang has mastered the core technology of gearbox through independent R&D. Thanks to its energetic R&D team and open communication environment, we are fortunate to have our iglidur high-performance plastic bearings loaded in batches in its gearbox system. Iglidur’s products are present in many popular models, including the natural gas tractor, J6L, Dragon VH, J7 mentioned in the beginning of the article. Especially, in the gearbox control system, iglidur shows its unique advantages: noise-reducing, durable, self-lubricating and maintenance-free. So, besides the control part, any other applications to recommend?

Figure 1. FAW Jiefang models for sale

iglidur is a registered trademark of igus plastic self-lubricating bearing series. At present, 47 kinds of materials using this prefix are included in the standard product library, which can be applied to various working conditions, and are also suitable for customers with different price acceptance. While the needs of customers continue to escalate, igus keeps adjusting its R&D direction.

Figure 2. drytech-box-iglidur material filter

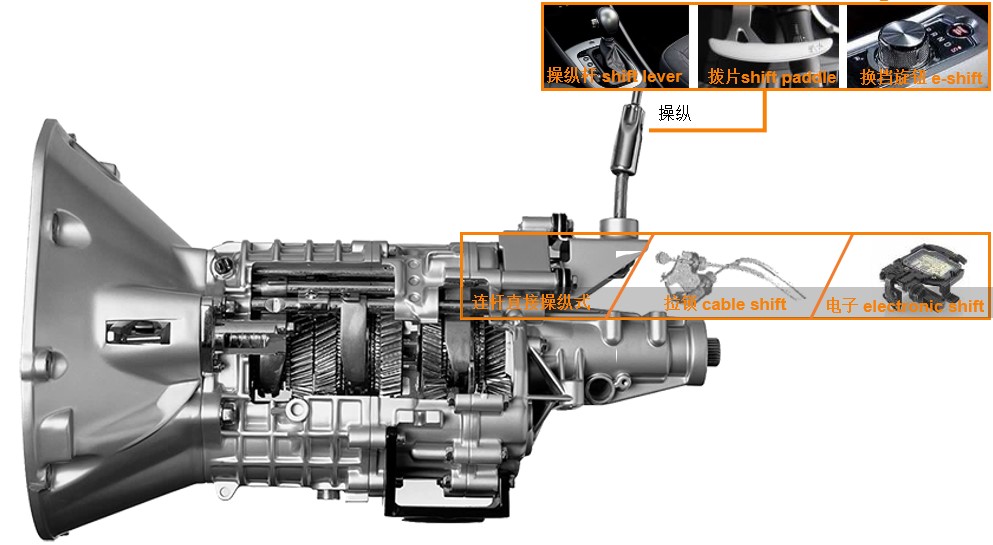

Roughly speaking, the gearbox system of both commercial and passenger cars can be divided into the control part and the transmission part. Drivers can shift gears through the joystick, paddle or knob. The control mechanism connected to the internal of the gearbox includes rod, zipper and electronic control. The working condition required for replacing traditional metal bearings with iglidur materials in the control mechanism is not very high, and we treat it as an entry-level application. Generally, an engineer who has just met igus will start conservatively from here. Or he may hesitate between ordinary plastics and iglidur plastics for a while. However, we firmly believe that iglidur materials have the optimized friction performance, which makes it the ideal choice for the auto engineers regardless of its relatively higher price.

Figure 3. Transmission control mechanism

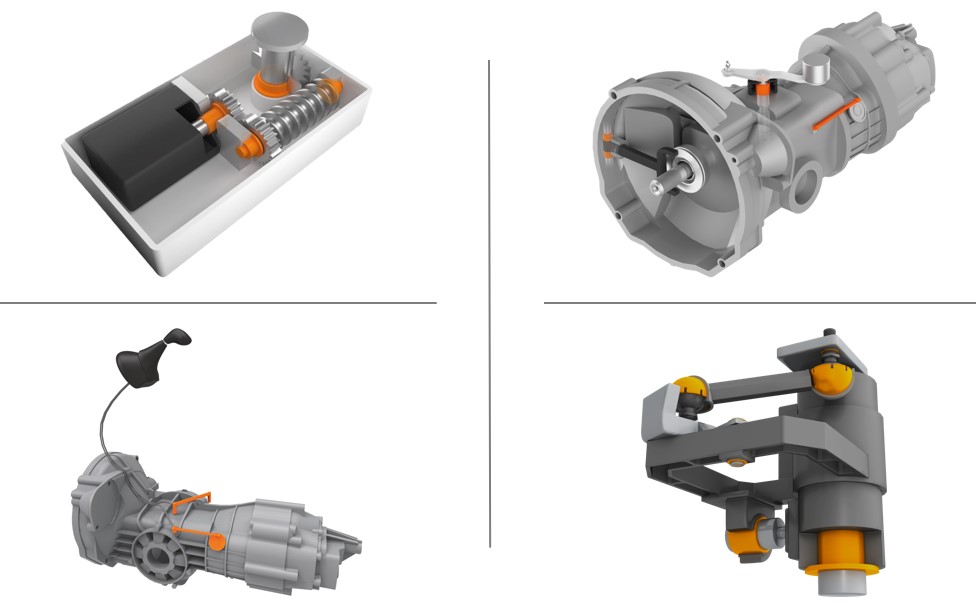

The shifting force is transmitted to the shift fork shaft inside the box. No matter it is the overall slip or just slip on the shaft, we can use iglidur H4, a bearing material. There are now other choices for cost reduction and upgrade of this material: iglidur H2 and HLW. It can be applied to the standard S type. One of our clients gave feedbacks that the pull-out force can meet more than 500N during the verification of the bench. Of course, it can also be structurally improved to achieve a higher pull-out resistance. The iglidur H series materials are stable in size and the friction coefficient is relatively low when immersed in gear oil and high temperature for a long time. The friction coefficient of sliding bearings is inevitably different from ball linear bearings, but if it’s cheaper, will the gearbox engineer still consider it?

Figure 4. Fork shaft bearings

The wear resistance of the gearbox shift fork feet is still a widely discussed topic, and now there are OEMs who have included igus’s block-type solutions as enterprise standard. Compared to other materials used before, like high-cost copper inserts, low-cost ordinary plastic coating, high-frequency quenching, ultrasonic welding, etc., iglidur inserts are superior for its lower price and higher performance.

Figure 5. Wear-resistant inserts for gearbox fork

Besides, in gearbox solenoid valves, electronic actuators, connecting rods, clutch release forks, P-stop parking or other positions, using iglidur plastic bearings, plastic gears and screws with iglidur plastic nuts will immediately let your system enjoy longer life without extra lubrication.

Figure 6. Other applications for variable speed systems

If you are interested in the application of high-performance engineering plastic products for gearbox systems, don’t hesitate to contact me:

Lynna Liu/刘银

Phone: 021-80366201

Email: lyliu@igus.net