Hack the Crisis: igus’ CEO shares lessons

Sebastian | April 23, 2020

Thoughts from Frank Blase, CEO, igus GmbH, as the Cologne, Germany-based company deals with the effects of the COVID-19 crisis.

“The situation changes daily for us. My planning horizon is 5 minutes.”

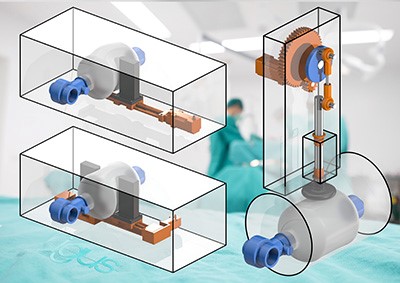

Two things are crucial: the health of our people, and keeping the plants open. Motion plastics are used in many areas of critical infrastructure: in the agricultural and food industry, water treatment and energy distribution. There are 200 such manufacturers in medical technology alone — established companies as well as start-ups that currently work flat out to develop new products — they use plain, linear and ball bearings or energy chains and cables from igus. They function in ventilators as well as in laboratory diagnostics or hospital beds.

At present, I can say that we are able to deliver 97% of all catalog parts from stock; worldwide local supply is ensured thanks to 14 of our factories worldwide — including in the USA. Our factory in Rhode Island has more than 20 million parts in stock and we deliver without delay. But this is a mere snapshot.

To keep it up, strong preventive measures have been implemented and are updated all the time. We started at the end of January, because we saw what had happened at igus China. I can count about 250 changes that we have made, both large and small. Some examples include: Fever measuring at the entrances, disinfectant dispensers everywhere, 1-hour cleaning cycles, changed shifts to spread people over the spaces, manufacturing of our own face masks, five new cafeterias built to give people space, face masks in productions after two weeks, 90% home office for all non-production colleagues (as of March 17), a “Daily Mail” sent to all colleagues for complete transparency, and hundreds of online trainings for the various tools and changes.

Our customers reach us via all channels, with the state-of-the-art new digital possibilities, such as virtual visits by smartphone, desktop sharing or online chat. We are paying a 25% hardship endurance to all of our manufacturing colleagues; all vacations can be deferred until end of 2021. Innovation goes on — we are just building our own “Hanover Messe.” We call it “The Home for Home Office Pioneers.” We open back up on April 20, the date that the Hanover Show would have opened.

Blase mentioned that there is a daily detailed update on igus.eu for ALL countries at:

https://www.igus.eu/info/daily-status

And there are also regularly updated pages that list all preventive measures at: