How important is quiet in linear guides?

Kevin Huang | June 9, 2022

Quiet machines and devices, whether in the household, laboratory or hospital, are easy on the nerves. Who does not know the sounds that disturb you directly. The elevator in the hotel at night, the dishwasher or the refrigerator that seems to reinvent itself in the evening. But the squeaking of a drawer when it is pulled open or the loud rolling of the new suitcase on the floor when you leave for your business trip at 5:10 in the morning are also unpleasant.

Quiet machines and devices, whether in the household, laboratory or hospital, are easy on the nerves. Who does not know the sounds that disturb you directly. The elevator in the hotel at night, the dishwasher or the refrigerator that seems to reinvent itself in the evening. But the squeaking of a drawer when it is pulled open or the loud rolling of the new suitcase on the floor when you leave for your business trip at 5:10 in the morning are also unpleasant.

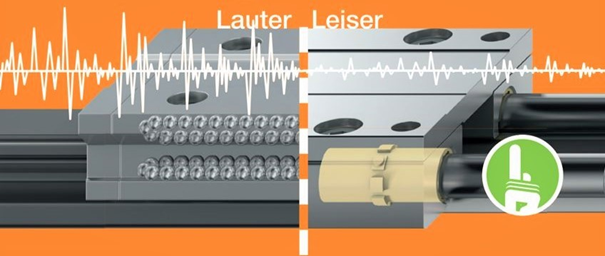

Granted, that doesn’t apply to everyone. But in principle, silence is very much appreciated. Similar effects occur with linear guides. Here, too, noise emissions can be reduced by making specific selections. This can be quickly understood when comparing ball guides and guide systems.

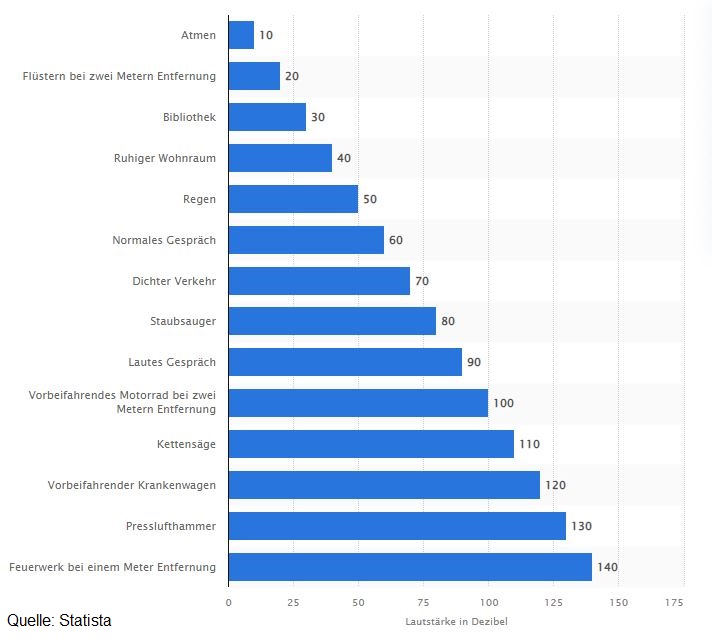

In ball guides and ball bearings in general, metallic bodies roll on a metallic surface, usually a rail or shaft. Metal on metal causes noise – all the more extreme when the systems are no longer brand new and show the first signs of wear. The grease required for each ball guide and placed in the bearing dampens the noise, but cannot suppress it effectively. In technical literature, this is referred to as mechanical vibrations caused by, for e.g., rotating components. Among others, the Institute for Occupational Safety and Health of the German Social Accident Insurance (IFA) provides deeper insights: the determination of the emission sound pressure level at the workplace is described in the basic standards DIN EN ISO 11201 to DIN EN ISO 11205. The basic standards DIN EN ISO 3744 and DIN EN ISO 3746 are of particular importance for determining the sound power level.

Linear guide systems, on the other hand, especially if they are based on technical high-performance plastics, slide – as their name suggests – over a running surface and produce only the slightest vibrations, which are at the same time dampened again by the plastic. This does not result in the same precision and stiffness, but a very pleasant smoothness. 45db are rarely exceeded.

You can find the practical test here: https://www.igus.eu/info/linear-guides-plastic-vs-metal-low-noise

The best way to compare this is with ice skating vs. roller skating. Roller skates? Yes, it’s due to my age, but of course I also skated on inliners. Or take them skiing. You move quickly and elegantly and almost silently. This is more or less the experience of a linear sliding guide.

Let us now think of the many applications in medical technology, laboratories, furniture, kitchens and other convenience products. And automation is also moving closer into our households. So-called moving robots with serving trays, as can already be seen increasingly in the catering industry, will “enrich” our daily lives. And if this is the coming trend, then these funny fellows should at least be quiet!