How igus® responds innovatively to challenges of modern manufacturing

Jen Chen | June 9, 2022

The year is 1989:

The Berlin Wall falls, the Astra 1A television satellite goes into operation, Voyager 2 delivers images of Neptune and the first igus® chainflex® cable is launched in the market.

We want to focus on the latter, despite the other important events.

Because the world of production is also in a constant state of change.

How igus responded to increasing automation

In the late 1980s, increasing automation brings with it faster and also more challenging applications. If you look at the production facilities, the energy chain is becoming more and more prevalent there. The company igus® also benefits from this with its plastic e-chains®.

Now, however, travels in manufacturing operations are getting longer and machine movements are becoming more dynamic.

This had sometimes devastating consequences for the cables commonly available on the market at the time.

Repeatedly occurs core breaks and corkscrews. Customers threatened to switch to alternative energy supply systems.

Accordingly, igus® had to act and develop a product that met the new requirements. This was the only way to secure the company’s own e-chain® business and offer customers an attractive overall package.

The beginnings of chainflex®

The first chainflex® cable was born and the dependence on less durable standard cables was history. This new type of cable brought with it specifications that are still used today (highly abrasion-resistant materials, short pitch lengths, cores wound in bundles, pressure-extruded outer and inner jackets).

The key to success: utmost care in planning and design and extensive testing in specially developed test machines.

As is well known, however, industrial development did not stop there, but soon brought completely different requirements for energy supply.

New applications in manufacturing bring new requirements

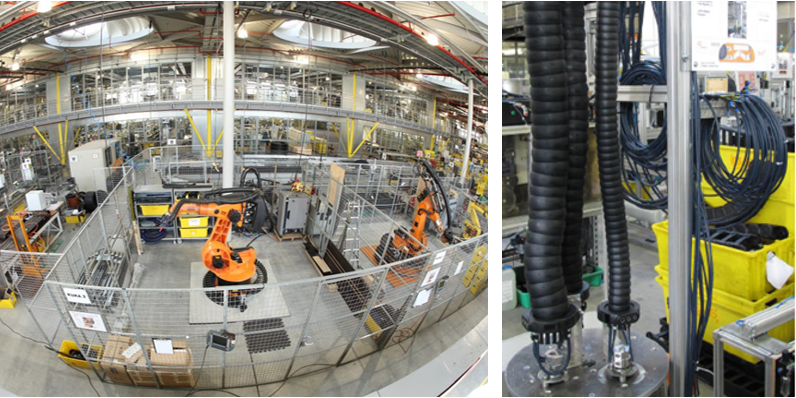

Increasingly complex production methods and the increased use of industrial robots and the associated dynamics also brought the already proven chainflex® cables to their limits.

If you think of a typical application within an automotive production line, for e.g., it quickly becomes clear what kind of movement could be affecting the cables here: torsion.

Again igus® was confronted with new problems and again there was no adequate solution on the market. A new product was needed.

Thanks to our experience from the development of chainflex® cables for linear applications, we were already able to draw on a wealth of experience in cable production. It was also clear what was important when developing a new type of cable: testing, testing, testing!

In the in-house test laboratory we created new qualification machines and in the further course also supplemented real industrial robots of established manufacturers.

In-house qualifications of torsion applications

Part of the qualification process is based on the so-called 3-fold or 10-fold torsion. Here, chainflex® CFROBOT cables are put through their paces in special 3D triflex e-chains®. They must withstand torsional loads of +/-180°/m up to +/- 360°/m.

The structure of the cables themselves differs significantly in some aspects from cables for linear motion. Whereas in e-chains® cables for e.g., tightly braided shields preferably provide long-lasting electromagnetic compatibility protection, they are rather counterproductive in torsion. The solution here is to rely on folded shields that can open and close and follow the torsional movement. Optionally, PTFE foils are also used, which enable the necessary compensating movements for individual elements of the cable.

Nowadays, igus offers a wide range of torsion-resistant cables with the CFROBOT series.

For example, servo cables, classic control and motor cables, and cables for controlling modern bus systems are available.

Challenge accepted

A brief look at the igus history shows: new challenges also always hold opportunities for new products and markets.

If the market does not offer adequate solutions, it is possible to create new production and test standards with good ideas, precision and a lot of care.

Are you also facing a new challenge in energy supply right now? We will be happy to help you choose the right cable. Feel free to leave a comment below the post or contact us.