Polymer coating – the way to protect parts from wear and tear

John Ji | September 15, 2021

Surface coatings have long since established themselves in all areas of everyday life. From frying pans to bicycle frames, the range of different coating materials and their properties is huge. A more recent phenomenon is the so-called tribological polymer coating. These are plastic-based coatings that have been additionally improved tribologically – i.e. for use as a friction-optimised surface. Thus, metallic surfaces not only protect against corrosion or scratching, but also against abrasion by other friction partners. The main advantage: polymer coatings can be applied to almost any surface and also solve wear problems in places where, classic plain bearings cannot be installed due to undercuts or limited installation space.

A metallic bearing with polymer coating (Source: igus GmbH)

The polymer coating process explained

Usually polymer coatings are applied as powder coatings. An overhead conveyor transports the parts to be coated through a coating plant where the powder is applied with spray guns or nozzles. In order for the powder coating to adhere to the component, it is necessary that the components to be coated are electrically conductive. The powder coating is applied by the tribo-coating process during spraying. As they emerge from the nozzle, the plastic particles are electrically charged by friction. This allows them to adhere to the finished workpiece. The polymer coating is then baked into the surface and finally forms a protective and even surface.

The advantages of tribologically optimised polymer coatings

As with plastic plain bearings, there are different formulations for polymer coatings. These can be optimised for various specifications. For example, there are particularly temperature-resistant polymer coatings, coatings for use in the food sector or for antistatic applications. The colour is also variable, but has an effect on the technical specifications of the coatings due to the amount of pigments required depending on the finish.

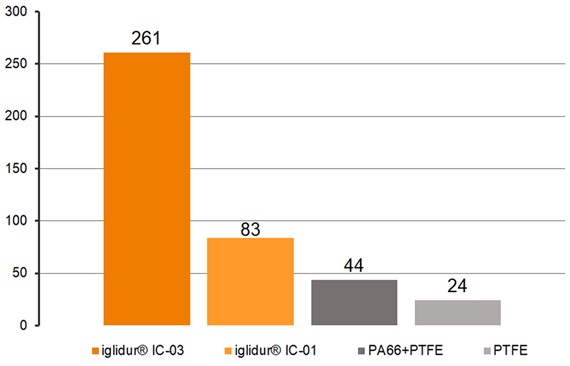

Service life [h]; short stroke 5mm, speed 0.1m/s, load 1MPa, temperature 23°C, shaft V2A (Source: igus GmbH)

Accordingly, different polymer coatings can also achieve different service life results when it comes to surface wear. It is therefore worthwhile to pay attention to the choice of the right coating material, especially for highly stressed parts such as valves, hinges or even baffles or similar.

We’d be happy to advise you!

Whether it’s choosing the right polymer coating, selecting the right component material or optimising the part geometry for the best possible coating results, our tribological polymer experts will advise you free of charge and without obligation and work with you to implement your project.