Comparison of sintered bushings: advantages and disadvantages

John Ji | July 16, 2021

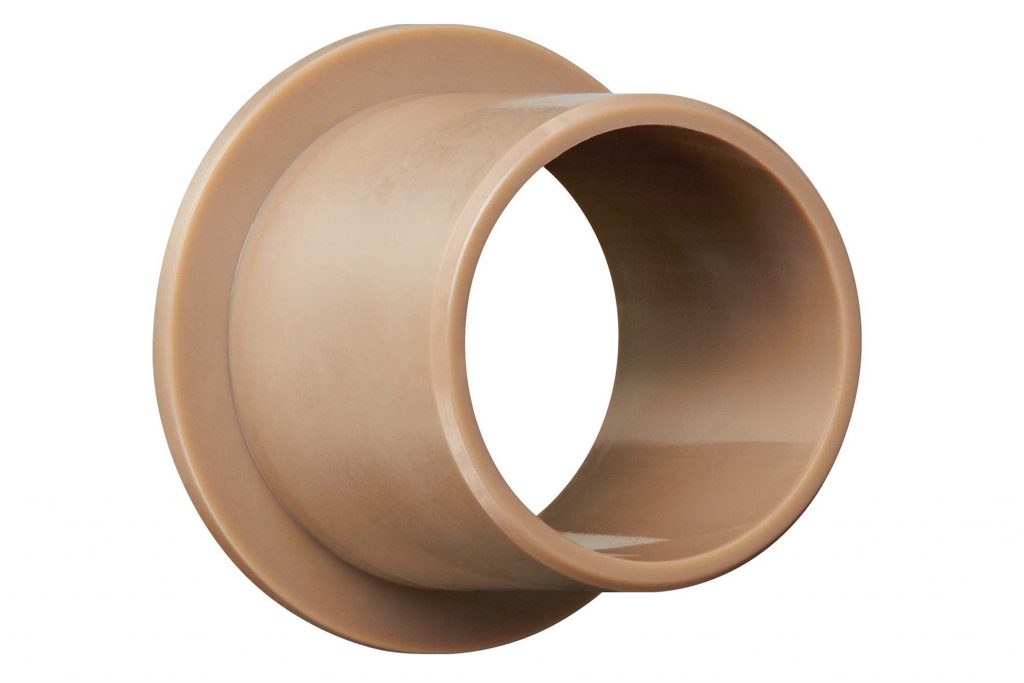

Sintered bushings or plain bearings made of sintered bronze are used in many bearing applications. They are comparatively cheap to procure, available in many dimensions and are sold as “self-lubricating” or “maintenance-free”. However, sintered bushings are by no means as universally applicable as many users think. In this blog post, I will take a closer look at the advantages as well as when the maintenance-free and self-lubricating bearing points can be implemented more reliably using plain bushes made of polymer.

How do sintered bushings actually work?

Sintered bushings are named after their manufacturing method – the so-called “sintering”. In this process, metallic or ceramic powder is first pressed into shape and then cured under high temperature. Depending on the process and material, this results in a rather coarse-pored component. This pore structure is the recipe for the success of sintered bushings. Because, the sintered bushings are impregnated with lubricating oil. The viscosity is selected in such a way that most of the oil remains in the pores at room temperature. If the bushing heats up during operation, e.g. due to friction, the lubricating oil escapes from the pores and distributes itself in the bearing. At higher speeds, a so-called lubricating wedge is created, which can eventually decouple the bearing from the contact surface and protect it from wear. And it is precisely here that the wheat is separated from the chaff.

Sintered bushings: when it has to work fast

The application profile for these bushings can also be derived from the fact that the self-lubricating effect depends almost entirely on the spread of the lubricating oil in the bearing point, and this effect only occurs with increasing frictional heat. Sintered bushings are primarily suitable for high-frequency or otherwise high-speed plain bearing applications. For slower or more sporadic intermittent applications, other types of plain bearings are more suitable. If the user wants to do without externally supplied lubrication or seals, there is hardly any alternative to plain bearings with solid lubricants. There are two main types of bearings. Metal composite bushings and polymer bushings.

The alternatives: composite metal and polymer

In order to maintain the dream of maintenance-free operation and self-lubrication, both solutions follow similar but in detail different approaches. While composite metal bushings rely on an extremely thin lubricating film made of PTFE or other plastics with good sliding properties, polymer bushings are usually made of a so-called compound. A material mixture in which the friction-optimising substances are added. Thus, the substance used as lubricant is distributed throughout the component. During operation, this solid lubricant is distributed microscopically finely in the bearing point, reducing friction. Even at low speeds. In addition, the variety of polymers offers a large number of possibilities for adaptation and use in many different applications.

Do you need help in choosing the right bushing material?

Our application specialists will be happy to advise you and design your bearing point together with you. We will determine the plain bushing with the best ratio of service life, costs and performance for you – by telephone, via digital visit or at your site. Free of charge and without obligation. Everything from one source.