Control of various desktop devices via digital I/O

Kevin Huang | October 21, 2020

Lean automation: igus Robot Control with 21 digital inputs and outputs

Behind Low Cost Automation is cost savings and great productivity provided by modularity, user-friendliness and reliability. To make robot programming and control even easier, igus has added the igus Robot Control to its Low Cost Automation range. What is special here is that up to 21 digital I/Os makes control of various desktop devices simple and efficient.

Digital I/Os in the world of automation – interface between device and robot kinematics

Digital I/Os in robot control systems allow communication between a desktop device and robot kinematics. Communication through an Ethernet interface between the control system and the computer can be quickly and easily programmed.

In practical application, you can have a robot insert small or milled parts into your desktop device or remove them from it. The digital inputs and outputs integrated into the control system enables the desktop device to receive commands such as “open door”, “close door”, “start” and “stop” to be programmed in the free-of-charge igus Robot Control.

Co-operative execution of commands for reliability

The sensors on the desktop device send signals such as “door open” or “door closed” to the control system. This prevents collisions. Laser printers, 3D printers and any other desktop devices that have the necessary interface can co-operate with the robot kinematics and be programmed in the software.

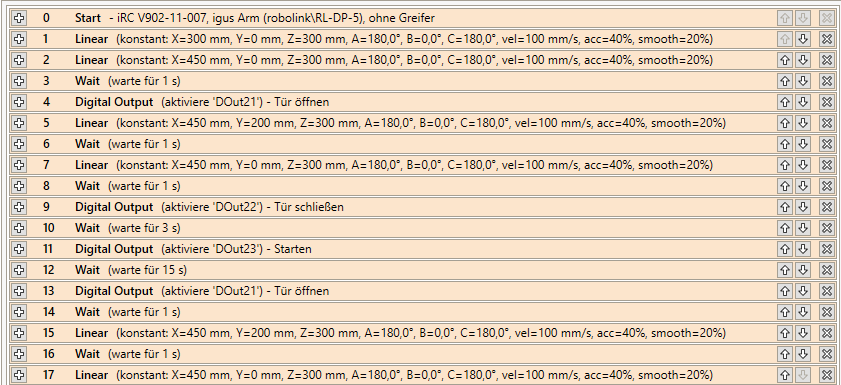

A practical example: robot application with laser device

This application is aimed at relieving staff of monotonous work. The connection between the lase box and igus Robot Control uses a D-sub connector plugged into the lase box. The other end of the cable is connected to the iRC’s digital I/O.

This I/O allowed communication between the lase box and the robot to be implemented and an interactive programme to be written. The programme allowed the robot to independently insert pins and remove them again and continuously repeat the process. They also allow commands to be sent to the desktop device (here the lase box). This allows commands such as “open door”, “close door”, “laser start/stop” to be programmed in the igus Robot Control software.

More tips for robot programming and robot control

Find out more about simple robot programming and how to get started here.