Energy and data transmission rolled out and connected in under 60 minutes

Jen Chen | May 29, 2020

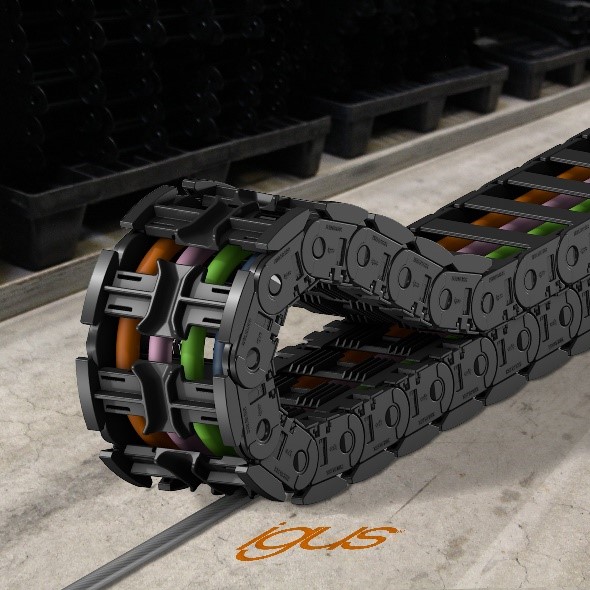

Revolutionary autoglide 5 system from igus does not need a guide trough

Guiding energy safely on long travels and at a low cost: this was the goal behind the development of the autoglide 5 from igus. The new energy chain system is specifically designed for horizontal use in intralogistics and on crane systems. The special feature: the energy supply is quickly installed, as it does not require a guide trough. Instead, it lies on a steel wire rope held in place by the e-chain contour.

Many users rely on busbar systems for power and data transmission in tight, compact spaces and for fast lane movements, for example, in storage and retrieval units. Their major disadvantage is that they are expensive to maintain, can only be used for power transmission as standard and must be cleaned regularly to avoid contact faults. igus has now developed the autoglide 5 to be able to safely guide horizontal cables at speeds of up to 4m/s and up to 80 metres travel distance even without a trough. “The autoglide 5 can easily be installed in the aisle on a rope or a profile. It is above all attractive with its low price, an 88 per cent shorter installation time compared to trough systems and its maintenance-free operation”, explains Christian Strauch, Industry Manager Intralogistics at igus. “Thus the new energy supply offers a real alternative to the busbar systems.”

Guide energy and data safely even without a trough

To install the autoglide 5, the intralogistics technician only needs the supplied metal rope, which he stretches on the aisle floor. Alternatively, guidance via a plastic rope or a profile is also possible. The e-chain can travel safely on the rope, because the igus developers have come up with a special guide concept. The underside of the chain links has a guide element in the middle, so that the energy chain can rest safely on the rope. For wear-resistant and precise rolling of the upper run of the chain on the lower run, the engineers relied on the igus autoglide elements. This system consists of comb-like injection-moulded crossbars that prevent the energy chain from sliding out. This allows the user to dispense with a guide trough completely.

Long-lasting, maintenance-free and easy to clean

Busbar systems, or the contacts of the pantograph, are very susceptible to wear and need be replaced after only one to two years. With the autoglide 5, igus has developed a durable and maintenance-free energy supply system made of high-performance polymers. igus is currently testing the long service life of the new energy chain in its own 3,800 square metre test laboratory. In the laboratory the autoglide 5 has already convinced with its quiet operation. At a speed of 2 metres per second the measured value was 63dB(A). Another advantage: “Since the autoglide 5, unlike the busbar system, has no open contacts, the aisle is easy to clean”, says Christian Strauch enthusiastically. igus offers the energy chain system already fully harnessed as a readychain with highly flexible chainflex cables.