Why can plastic plain bearings be used in the engine compartment?

Lynna Liu (刘银) | May 21, 2020

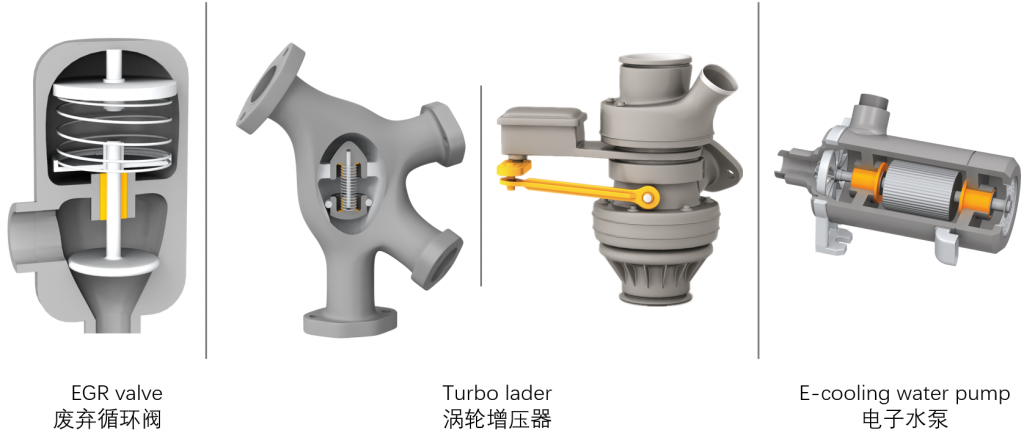

Plastic and high temperatures? Yes, even as a connection to actuators of turbochargers or in EGR valves, iglidur® high-temperature materials are represented millions of times as plain bearings or coupling rods. With permanent application temperatures of up to 250 ° C and briefly 300 ° C, plastic plain bearings are used in almost all engine components. Only when it comes to the engine or exhaust system, the temperatures and p * v values often become too high, so that metal bearings have to be set. Due to the hydradynamic effect, enormous speeds can also be achieved. For example, iglidur® materials often replace very expensive ceramic or graphite bearings.

Plastic and liquids? That swells! Yes, if the wrong plastics are used in the coolant or oil circuit, they absorb the liquid and expand. In the worst case, the bearing block and the engine component fails. PPS based materials even disintegrate in hot coolants or oils. So what to do? In the below Some iglidur® materials that are resistant in the engine compartment are listed in the table:

- iglidur® H4 – the standard up to +200 ° C

- iglidur® X – extremely temperature-resistant up to 310 ° C for a short time

- iglidur® H1 – exceptionally low coefficients of friction

- iglidur® H2 – the low-cost solution

- iglidur® G1 – the standard for low temperatures up to + 180 ° C

If you happen to have similar application requirements, please contact me:

刘银/Lynna Liu

tel:021-80366201

E-mail:lyliu@igus.net